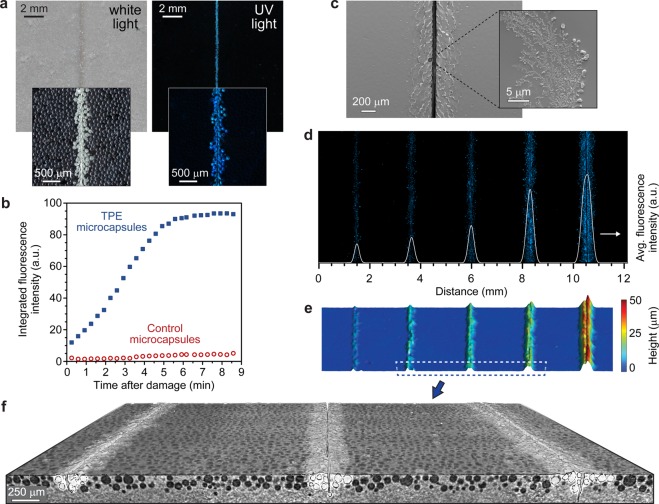

Figure 3.

Evaluation of damage detection performance in transparent epoxy coatings. (a) Photographs of an epoxy coating containing 10 wt % TPE microcapsules under illumination with white light and UV light after being scratched with a razor blade. Insets show stereomicrographs of the coating under similar illumination. (b) Time-dependent fluorescence microscopy measurements illustrating rapid development of a fluorescence signal after damage. A control coating incorporating microcapsules with only hexyl acetate in the core exhibits negligible change in fluorescence after damage. (c) SEM images illustrating solid TPE deposits in the shear region adjacent to the primary scratch damage. (d–f) Characterization of an epoxy coating containing 10 wt % TPE microcapsules with damage of varying size (average scratch depths from left to right: 94, 140, 171, 222, and 376 μm): fluorescence micrograph and overlaid fluorescence intensity profile (d), surface topology from profilometry (e), and magnified view of a 3D micro-CT reconstruction (f). Profilometry does not sufficiently resolve the scratch from the adjacent sheared region. In panel f, intact microcapsules are rendered as black; ruptured microcapsules and damaged areas of the surface are white; the epoxy polymer matrix is shaded gray.