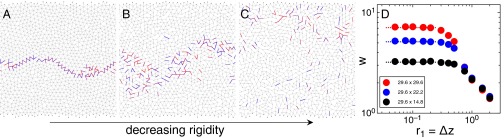

Fig. 1.

Transition in material failure due to changing material rigidity. As bonds between nodes are removed from a random spring network, the failure behavior changes continuously from brittle cracking to diffuse breaking. In A–C, the sample is stressed uniaxially in the vertical direction. (A) A thin crack is observed in a rigid material. Only a small amount of meandering occurs. (B) The intrinsic width of the crack grows as the material becomes less rigid. (C) The crack width saturates at the size of the system when the rigidity of the material decreases toward the limit where the bulk and shear moduli vanish. (D) The width of the zone in which failure occurs, w, increases continuously as the rigidity, , decreases and plateaus at a value , indicated by the dotted line. Once the crack width reaches the system size, only diffuse breaking occurs. The sample sizes are indicated in the legend: the horizontal width of the sample (perpendicular to the direction of applied stress) is kept constant at 29.6 and its vertical length (parallel to the pulling direction) varies from 14.8 to 29.6 (measured in units of the average interparticle spacing). Simulations use dissipative Newtonian dynamics, as detailed in Model Systems and Breaking Protocols.