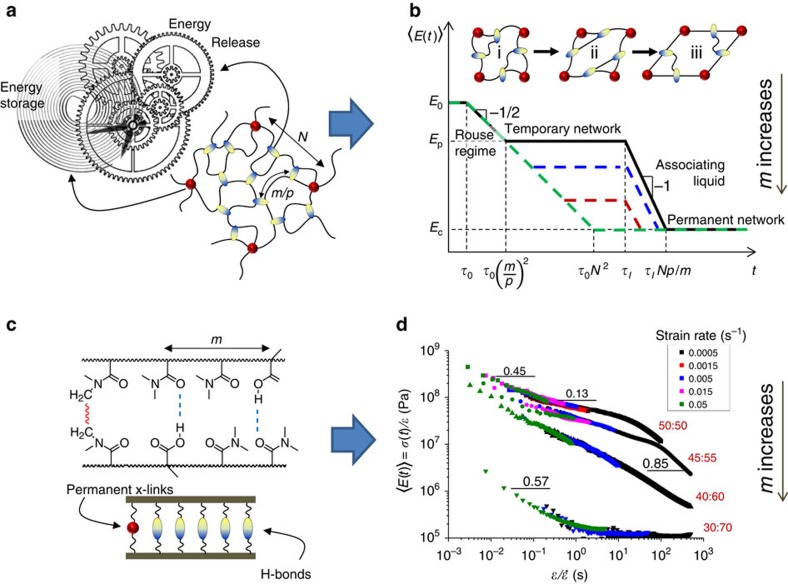

Figure 1. Dynamic networks.

(a) Mechanical watch machinery—an inspiration for the design of a dual polymer network with chemical crosslinks (dots) for energy storage and reversible physical crosslinks (ovals) for controlled energy release: N and m/p—number of monomeric units between the chemical and physical crosslinks, where m—degree of polymerization between associating groups and p—degree of conversion of the associating groups into crosslinks. (b) At constant strain rate  , the evolution of the time-average network Young's modulus

, the evolution of the time-average network Young's modulus  during deformation

during deformation  is controlled by two characteristic relaxation times: τ0—monomeric timescale, τl—lifetime of physical crosslinks. At (m/p)2τ0<t<τl, Rouse-like relaxation of the network strands

is controlled by two characteristic relaxation times: τ0—monomeric timescale, τl—lifetime of physical crosslinks. At (m/p)2τ0<t<τl, Rouse-like relaxation of the network strands  is followed by the physical network modulus plateau at Ep≅E0p/m. After pausing at the plateau (ii), the deformation process continues through recurring dissociation/re-association of the physical crosslinks. In this time window (τl<t<(Np/m)τl∼hours), the system behaves as a viscous liquid

is followed by the physical network modulus plateau at Ep≅E0p/m. After pausing at the plateau (ii), the deformation process continues through recurring dissociation/re-association of the physical crosslinks. In this time window (τl<t<(Np/m)τl∼hours), the system behaves as a viscous liquid  , while the physical network rearranges in a new stress-free configuration (iii)25. At t>(Np/m)τl, the ‘flow' is terminated by the covalent network resulting in the second modulus plateau at Ec≅E0/N. (c) Methacrylic acid (MAAc)-co-N,N-dimethylacrylamide (DMAA) hydrogels include covalent crosslinks (dot) and hydrogen-bonds between MAAc and DMAA groups (ovals), where m depends on the copolymerization ratio. (d)

, while the physical network rearranges in a new stress-free configuration (iii)25. At t>(Np/m)τl, the ‘flow' is terminated by the covalent network resulting in the second modulus plateau at Ec≅E0/N. (c) Methacrylic acid (MAAc)-co-N,N-dimethylacrylamide (DMAA) hydrogels include covalent crosslinks (dot) and hydrogen-bonds between MAAc and DMAA groups (ovals), where m depends on the copolymerization ratio. (d)  was extracted from stress-strain relations

was extracted from stress-strain relations  , measured at 3 °C at constant

, measured at 3 °C at constant  , ranging from 0.0005 to 0.05 s−1 (Supplementary Fig. 3). The standard deviation of the average of three separate experiments at each strain rate is within 5%. The four curves correspond to different MAAc:DMAA molar ratios (50:50, 45:55, 40:60 and 30:70), which determine the physical crosslinking density. The slopes of the curve at different time windows are indicated above the horizontal short lines. Consistent with the theoretical prediction, Ep decreases with increasing m. The

, ranging from 0.0005 to 0.05 s−1 (Supplementary Fig. 3). The standard deviation of the average of three separate experiments at each strain rate is within 5%. The four curves correspond to different MAAc:DMAA molar ratios (50:50, 45:55, 40:60 and 30:70), which determine the physical crosslinking density. The slopes of the curve at different time windows are indicated above the horizontal short lines. Consistent with the theoretical prediction, Ep decreases with increasing m. The  analysis was chosen because time–temperature superposition fails to describe dynamics of the associating networks (Supplementary Fig. 4) governed by two distinct relaxation processes24: segmental motions within polymer chains (τ0) and dissociation of H-bonds (τl). Validity of the linear viscoelasticity approximation has been verified (Supplementary Equation 29; Supplementary Fig. 5).

analysis was chosen because time–temperature superposition fails to describe dynamics of the associating networks (Supplementary Fig. 4) governed by two distinct relaxation processes24: segmental motions within polymer chains (τ0) and dissociation of H-bonds (τl). Validity of the linear viscoelasticity approximation has been verified (Supplementary Equation 29; Supplementary Fig. 5).