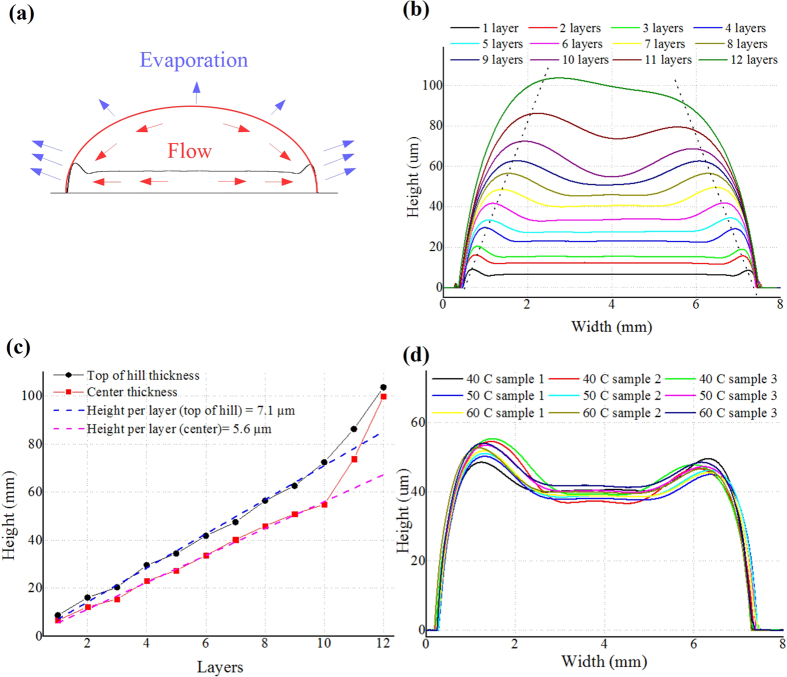

Figure 4. Features of inkjet-printed SU-8.

(a) A sketch to demonstrate the “coffee ring” effect during ink curing in a cross-section view. The red curve stands for the deposited liquid-phase ink and the black line stands for the final shape after the solidification of the ink. The blue arrow shows the evaporation of the solvent and the red arrow shows the flows within the liquid-state ink during curing. (b) The profile of the inkjet-printed rectangular “pad” (7 mm × 7 mm) prototypes for a different numbers of layers. The two dotted lines mark the “coffee ring” hill-top trend for an increasing thickness. (c) Printed SU-8 thickness in the center of the “pad” (“center”) and at the hill-top of the “coffee ring” (“top of hill”) for different numbers of printed layers. (d) The profile of the inkjet-printed rectangular “pad” (7 mm × 7 mm for 7 layers) prototypes at various printing platform temperatures (40 °C, 50 °C and 60 °C; 3 samples at each temperature).