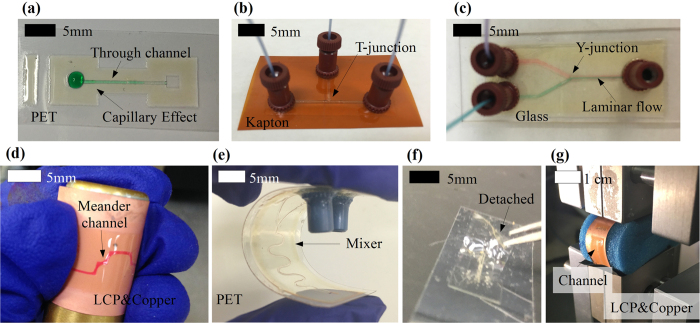

Figure 6. Examples of fully inkjet-printed microfluidics structures.

(a) A straight microchannel on PET substrate. A drop of green-dyed water was dripped on one of the two channel openings and the capillary effect drove the water to enter the channel. (b) A T-junction and three microfluidic channels along with three installed connectors on Kapton substrate. (c) A Y-junction and three microfluidic channels along with three installed connectors on glass. One of the two inlets was fed with green-dyed water and another inlet was fed with red-dyed water. A laminar flow appeared when the two different color-dyed flows merged. (d) A meander microchannel on LCP substrate (coated by copper) bent in tension around a 14-mm-diameter rod with red-dyed water filling the channel. (e) A fully inkjet-printed microfluidics mixer on PET substrate bent in compression between two fingers. (f) A microfluidics device was detached from the substrate and was bent by a tweezer for a radius down to 0.5 mm. (g) A microfluidics device was bent by a TestResources four point bend tester for a radius of 1 cm.