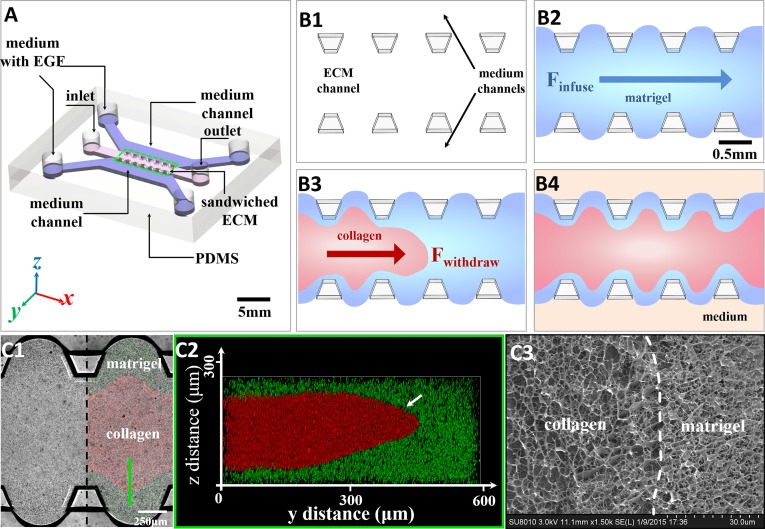

Fig. 2.

The formation of the sandwiched ECM in the microfluidic device and the ECM structure characterization. (A) Diagram of the polydimethylsiloxane (PDMS)-based microfluidic chip. The core consists of a 3D sandwiched ECM in the center, shouldered by two medium channels of medium with EGF. (B, 1–4) The formation process of the sandwiched ECM. First, the liquid Matrigel (blue) was injected into the ECM channel (B, 2). Then the liquid collagen gel (red) substituted for the Matrigel in the middle part by negative pressure from the outlet (B, 3). After injection, the sandwiched ECM was cured at 37 °C for 30 min before the side channels were filled with medium (B, 4). (C, 1–3) The characterization of the sandwiched ECM in the microfluidic device. The confocal microscopy shows the planar view (C, 1) and z-stack images (C, 2) of the sandwiched gel. Imaging using a cryo-SEM figure (C, 3) shows the Collagen I–Matrigel interface in the sandwiched ECM, which indicates that the initial collagen–Matrigel matrices had a distinct interface without obvious fusion.