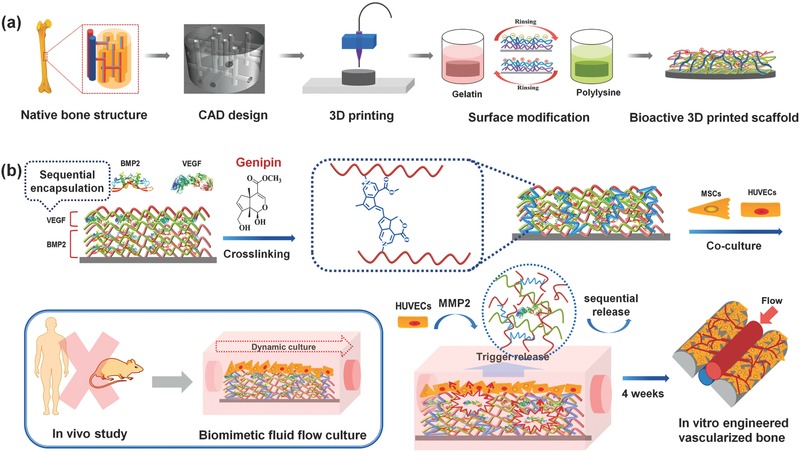

Figure 1.

a) Schematic illustration of the fabrication process of nanocoating modified 3D bioprinted scaffolds. According to the native bone structure, the biomimetic perfused scaffold combining bone support and vascular channels was designed and printed by FDM printer. Then surface modification process was performed to obtain a bioactive vascularized bone construct. b) Schematic representation of sequential adsorption and biologically inspired release of growth factors in the nanocoating film. The rhBMP‐2 was adsorbed in first 15 dual‐layers and then rhVEGF was adsorbed in the top 5 dual‐layers together with genipin crosslinking reaction. When MSCs and HUVECs were co‐cultured in dynamic fluid, the secretion of MMP2 by HUVECs could trigger the release of growth factors. After 4 weeks of culture, the vascularized bone structure would be formed in vitro.