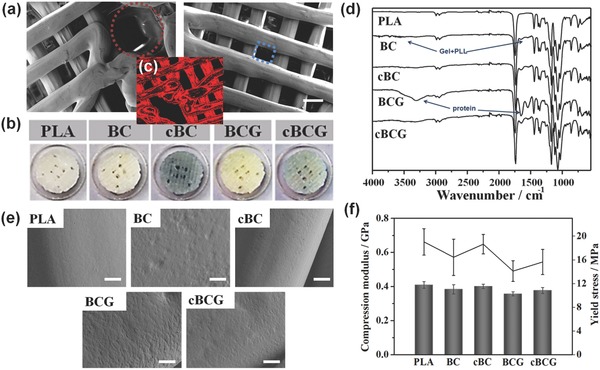

Figure 2.

a) Microstructural characterization of 3D bioprinted perfused scaffold based on CAD design by SEM. The red circle shows 500 μm vascular channels and the blue square shows 200 μm pores of bone scaffold. The scale bars indicate 200 μm. b) Images of different scaffolds, including PLA, bioactive nanocoating (Gel/PLL)20 modified PLA (BC), Gnp crosslinked bioactive nanocoating [(Gel/PLL)20]GnP modified PLA (cBC), bioactive nanocoating with growth factors (BCG), and Gnp crosslinked bioactive nanocoating with growth factors (cBCG). c) Red auto‐fluorescent image of cBC or cBCG. d) ATR‐FTIR spectra of different scaffolds. e) Surface morphologies of the different coating modified scaffolds, untreated PLA served as a control. A nanoscale islet‐like feature uniformly distributed over the surface and the adsorption of protein increased the roughness, whereas the crosslinking process weakened these changes. f) Mechanical properties of 3D bioprinted scaffolds. After the post fabrication modifying process, 3D bioprinted scaffolds maintained native bone‐like mechanical strength.