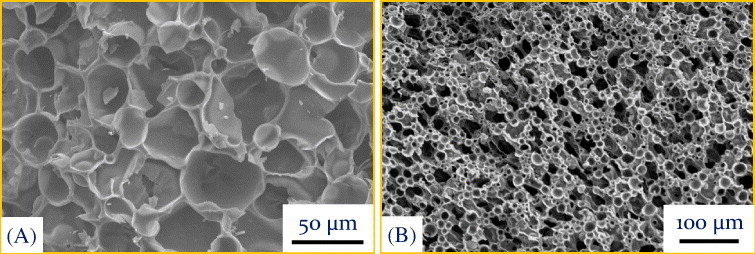

Figure 4.

Microstructures of porous ceramics produced via the direct foaming technique: (A) SiOC-based closed-cell structure obtained using 50% polysiloxane and 50% poly(methyl methacrylate-co-ethylene glycol dimethacrylate) microbeads (∼20 μm) and (B) SiOC-based open-cell structure obtained using 54% polysiloxane, 36% poly(methyl methacrylate-co-ethylene glycol dimethacrylate) microbeads (∼20 μm), and 10% low-density polyethylene. The raw materials were compounded using a counter-rotating twin-screw extruder. The extruded samples were saturated with gaseous CO2 at room temperature for 24 h under a pressure of 5.5 MPa. Thermodynamic instability was then introduced by lowering the pressure at a rate of 3.9 MPa s-1. The foamed samples were cross-linked by doping a catalyst and subsequently heating the specimen up to 200 °C. The specimen was then pyrolyzed at 1200 °C for 1 h in argon.