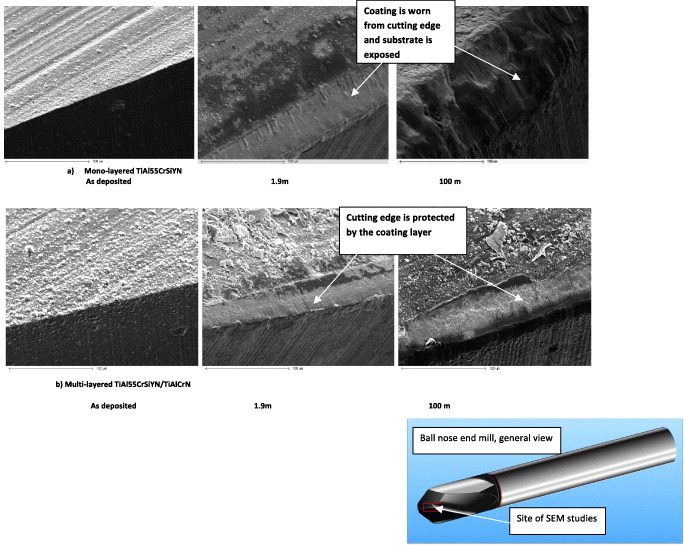

Figure 10.

SEM images of surface morphology versus length of cut of the worn coated ball-nose end mills with (a) TiAlCrSiYN monolayered and (b) TiAlCrSiYN/TiAlCrN multilayered coatings. Tool: carbide ball-nose end mill, D = 10 mm; workpiece-H13 tool steel, hardness HRC 53–55, speed: 500 m min−1; feed, 0.06 mm per tooth; axial depth, 5.0 mm; and radial depth, 0.6 mm. (Reproduced with permission from [17], Elsevier.)