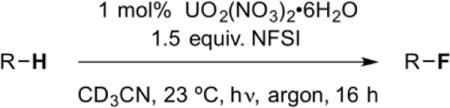

Table 3.

Fluorination of Oxygenated Molecules

| |||

|---|---|---|---|

| Entry | substrate | product | Yield [%][a] |

| 1 |

|

n/a | No fluorination |

| 2 |

|

|

Trace |

| 3 |

|

|

Trace |

| 4 |

|

|

Trace |

| 5 |

|

|

Trace |

| 6 |

|

n/a | No fluorination |

| 7 |

|

n/a | No fluorination |

| 8 |

|

|

Trace |

| 9 |

|

|

13 |

| 10 |

|

|

10 |

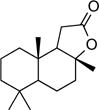

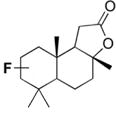

| 11 |

|

|

26[b] |

| 12 |

|

n/a | No fluorination |

| 13 |

|

n/a | No fluorination |

| 14 |

|

n/a | No fluorination |

Yield determined by NMR through integration relative to a methyl acetate internal standard;

1.6:1 C2/C3 fluorination