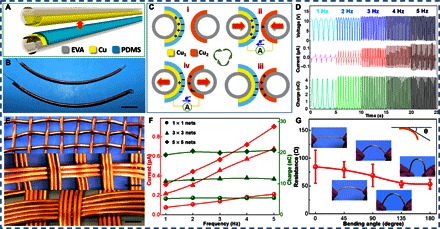

Fig. 4. Structural design of an F-TENG.

(A) Schematic diagram and (B) photograph (scale bar, 1 cm) of a pair of single F-TENG units, consisting of a Cu-coated EVA tube and a PDMS-covered Cu-coated EVA tube. (C) Schematic illustration of the working mechanism of the F-TENG under parallel contact-separation motion. (D) Electrical outputs of a pair of F-TENG units, which included VOC, ISC, and QSC, at various motion frequencies (1 to 5 Hz). (E) Photograph of the wearable self-charging powered textile with knitting patterns of 1 × 1, 3 × 3, and 5 × 5 nets (all scale bars, 1 cm). (F) Triboelectric output performance of the three network textiles. (G) The electric resistance of the Cu-coated EVA tube at different bending angles (0° to 180°) (insets show the photograph of the Cu-coated EVA tube at different bending angles).