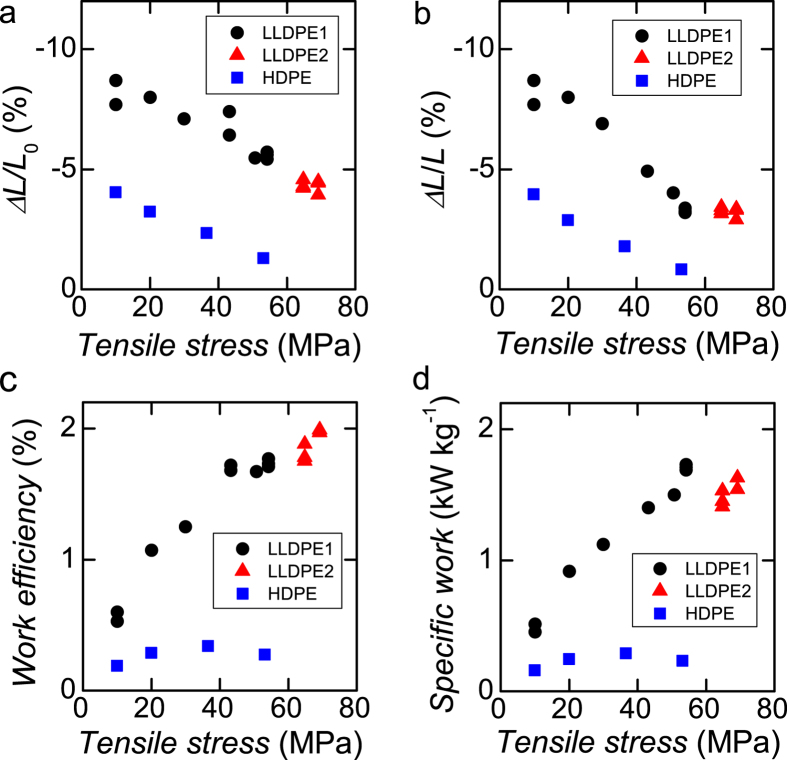

Figure 2. Actuation of coiled LLDPE and HDPE fibre actuators under various tensile stress.

The black closed circles and red closed triangles are coiled LLDPE fibres fabricated by twisting fibres of ϕ170um diameter under tensile stresses of 20 MPa (LLDPE 1, c = 0.7) and 30 MPa (LLDPE 2, c = 0.5), respectively. The blue closed squares are coiled HDPE fibres fabricated by twisting fibres with ϕ180um diameter under tensile stresses of 20 MPa (LLDPE 1, c = 1.1). The HDPE fibres were broken by twisting under tensile stresses of 30 MPa. All actuators in these figures were driven for 0.65–1.1 sec. (a) Displacement of the actuators normalized by actuator length under tensile stress. (b) Displacement of the actuators normalized by natural length of the actuator. (c) Work efficiency estimated from the work shown in (b) divided by the heat change of the actuator. (d) Specific work of the actuators. Plots are shown only for actuators driven for 0.65–0.7 sec.