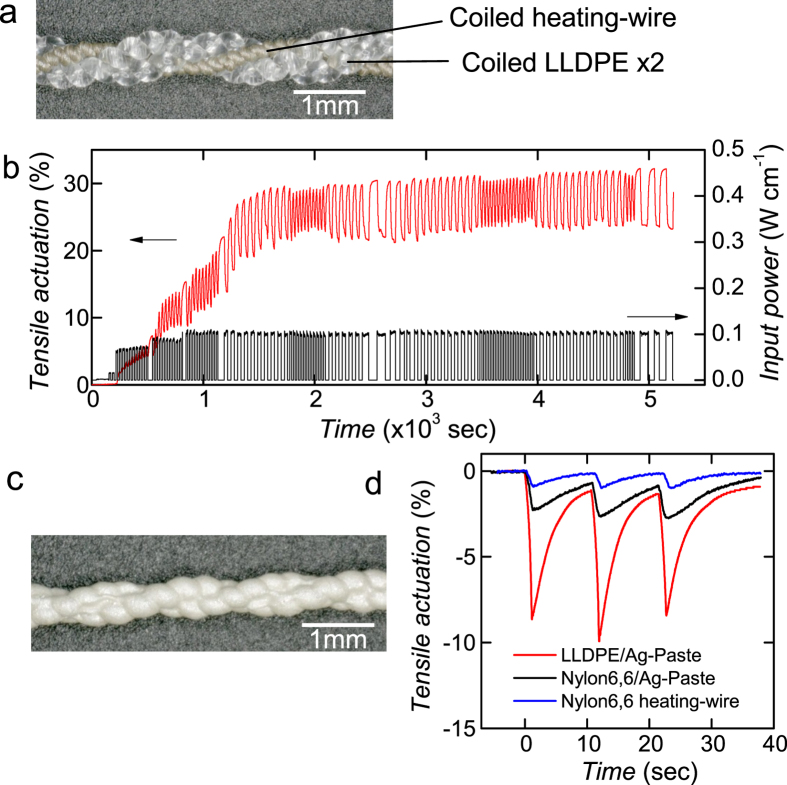

Figure 4. Coiled LLDPE actuators composed of coiled LLDPE and an electrical resistive heater.

(a) Photographs of 3-ply yarn composed of a couple of coiled LLDPE fibres with ϕ0.2 mm diameter and heater wire with 100 denier (LLDPE/heating-wire). (b) Actuation of the LLDPE/heating-wire using 110 pulses of input power, including initialization steps of 30 pulses (up to 1500 sec). (c) Photographs of the 2-ply yarn of coiled LLDPE fibres with ϕ0.2 diameter coated with a conductive elastomer (LLDPE/Ag-paste). (d) Actuation of LLDPE/Ag-paste by electrical resistive heating with an input power of 0.14 W cm−1 for 1 sec. 2-Ply yarns of conductive elastomer-coated coiled nylon6, 6 fibres (nylon6, 6/Ag-paste, c = 1.2) and Ag-plated coiled nylon6, 6 multifilament with 300 denier (nylon6, 6 heating-wire) were also fabricated and measured for comparison. All actuators have almost same cross sectional area of 0.03 mm2. The nylon6, 6 heating-wire of 100 denier was also used as heater wire shown in (a). As the nylon6, 6 heating-wire exhibited very small actuation, a contribution of the actuation on the LLDPE/heating-wire is negligible.