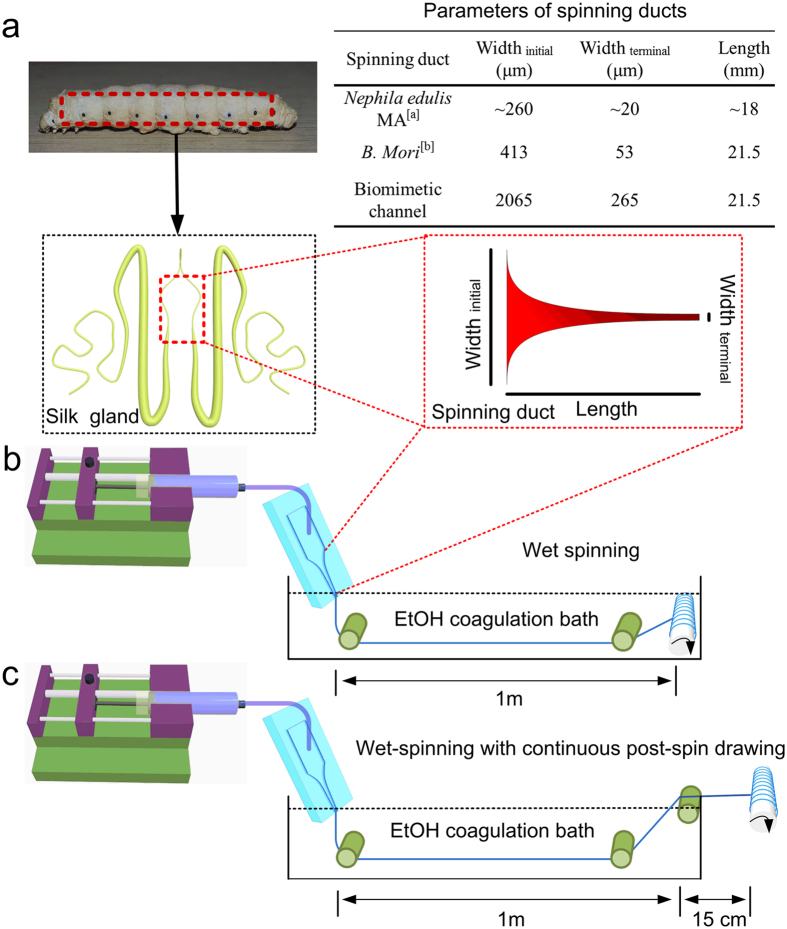

Figure 1. Schematics of the microfluidic spinning process of recombinant spider dragline silk.

(a) Geometries of the spinning ducts of spider and silkworm. Both contracting spinning ducts enable the proteins to be compact and orderd under shearing and elongation forces. A biomimetic, microfluidic channel was designed to emulate the specific geometry of the silkworm silk gland. (b) Wet-spinning process (WS). (c) Wet-spinning process with continuous post-spin drawing in the air (WS-PSD). aThe diameter of the tapered N. edule S-duct decreases as a two-stage hyperbolic curve from the funnel, up to a zone called the draw down taper, where the diameter decreases more rapidly, following a two-stage exponential function25. bThe diameter (Y) of the lumen of the silkworm (B. mori) duct decreases following a second-order exponential regression line with distance from the start of duct (X). Regression line Y = A(1/(1 + exp(BX)) + C(1/(1 + exp(DX)), where A = 238, B = 6.18E-05, C = 588, D = 0.003, and R2 = 0.98826.