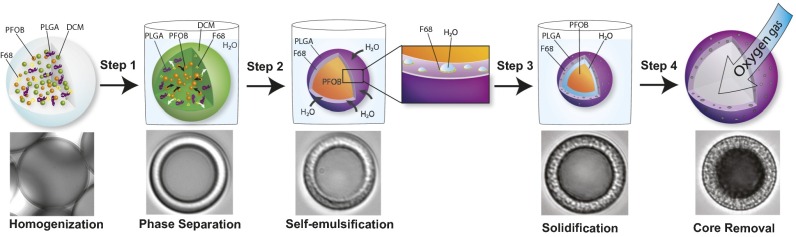

Fig. 1.

Schematic representation of the phase separation/self-emulsification strategy used to fabricate PHMs with highly tunable shell properties. A DCM solution containing PLGA (shell material), PFOB (nonsolvent), and Pluronic F-68 (self-emulsifying agent) is homogenized in water to yield stable dispersions. (Step 1) As the droplet solvent (DCM) diffuses into the aqueous phase, the nonsolvent (PFOB) phase separates to form a droplet with a core–shell structure. (Step 2) The aqueous phase diffuses into the DCM-rich droplet, which, in the presence of F-68, results in the spontaneous formation of water-in-oil (w/o) nanoemulsions within the PLGA-rich shell phase. Control over the precipitation rate of the PLGA governs the extent of pore formation. (Step 3) The droplets are allowed to ripen overnight to harden the PLGA shell. (Step 4) Freeze-drying yields gas-filled particles, suggesting that a fraction of the pores coalesced during fabrication to yield a network of capillary channels within the shell. Time-lapse photomicrographs showing the production of PHMs are shown underneath each schematic.