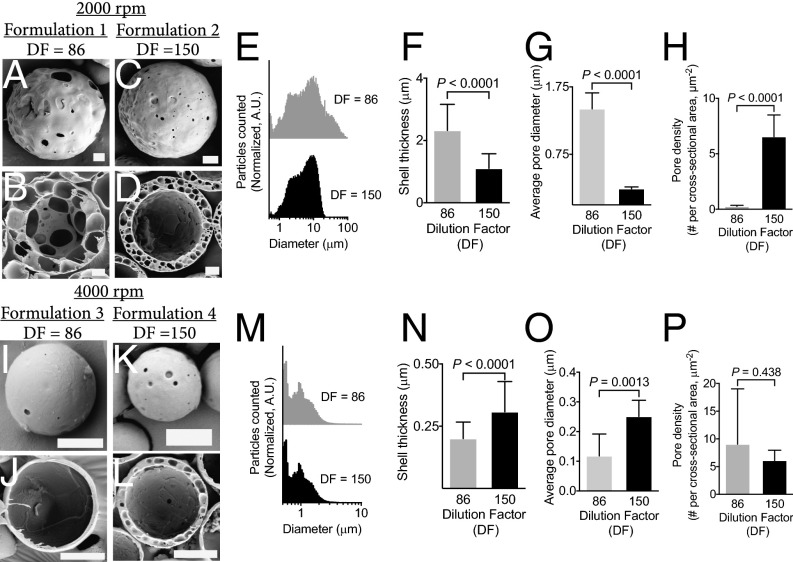

Fig. 2.

Control over particle morphology and size is achieved by manipulating the processing parameters. (A–D) Homogenization at 2,000 rpm (Silverson Machines, Inc.; East Longmeadow, MA; model: L5M-A) followed by low (A and B) or high (C and D) dilutions altered the precipitation rate of the PLGA shell to generate PHMs with varying internal morphologies. (E) Lower DFs increased the polydispersity of PHMs fabricated at slow homogenization speeds. (F–H) Lower DFs lead to PHMs with thicker shells (F) and larger pore diameters (G), but decreased pore densities (H), compared with higher dilutions. (I–L) Homogenization at 4,000 rpm (Silverson Machines, Inc.; East Longmeadow, MA; model: L5M-A) followed by slow (I and J) or fast (K and L) precipitation rates. (M) Increased homogenization speed reduced the polydispersity of PHMs, regardless of DF. (N–P) Lower DFs produce PHMs with thinner shells and smaller pore diameters, but similar pore densities as higher dilutions. [Scale bars: 10 μm (A–D); 2 μm (I–L).]