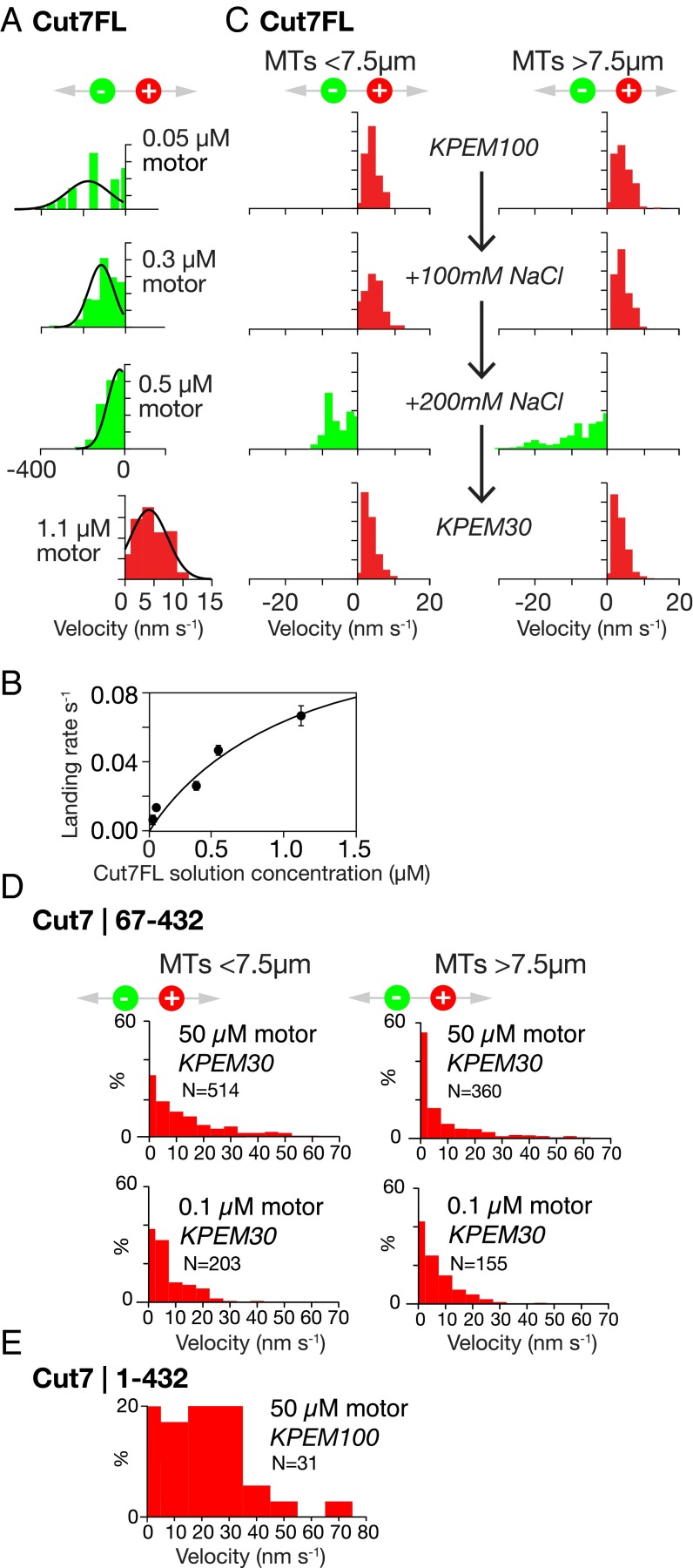

Fig. 2.

In vitro motility. (A) Directional reversal by increasing the surface density of Cut7FL. Increasing motor density slows MT sliding and ultimately drives directional reversal. Note the expanded velocity axis for plus end-directed stepping. The concentrations shown are the solution concentrations of Cut7FL used to prepare the surfaces. (B) Control experiment showing that this concentration scales predictably with the MT landing rate, which in turn is proportional to the surface density of active motor. (C) Lawns of Cut7FL motors can be converted back and forth between plus and minus end-directed stepping by serially changing the ionic strength. All data are from the same flow cell with a dense surface of Cut7FL. The initial buffer was KPEM100 gliding buffer, 1 mM ATP (Methods), followed by the same plus 100 mM NaCl, and then the same plus 200 mM NaCl (note the directional reversal). Finally, flushing with KPEM30 gliding buffer, 1 mM ATP reverted the motor to plus end-directed stepping. Data from short (<7.5 µm) and long (>7.5 µm) MTs are very similar. An MT length of 7.5 µm was chosen to split the data approximately in half (Movie S8). (D) In 30 mM PIPES pH 6.9 and 0.1 mM ATP, Cut7|67–432 monomers drive MTs to slide with plus ends trailing, independent of MT length and motor density. (Movie S9). (E) Cut7|1–432 monomers also drive MTs to slide with plus ends trailing (buffer, 100 mM PIPES pH 6.9 and 0.1 mM MgATP) (Movie S10).