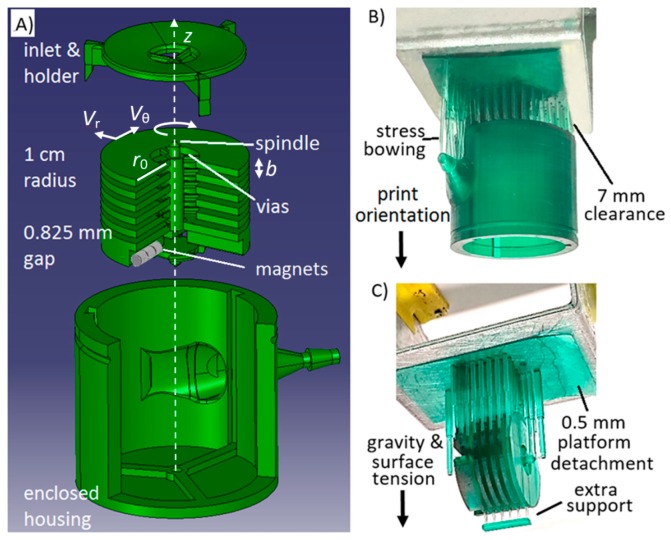

Figure 2.

Computer design and 3D printing of µTesla. (A) The µTesla pump was comprised of three parts: cap with pivot, the rotor with vias and pockets for magnets, and the enclosed housing with fluidic spout and bottom pivot. The computer design was then printed in a DLP 3D printer. The print was upside down as pictured in (B,C) and subjected to gravity pull; (B) To reduce surface tension pulling down large areas of the enclosed housing’s bottom, substantial clearance was required along with numerous supporting posts to prevent excessive warping and detachment; (C) The rotor required extra support to keep the disks straight. Additional resin platform was added to ensure adhesion to the metal print stage.