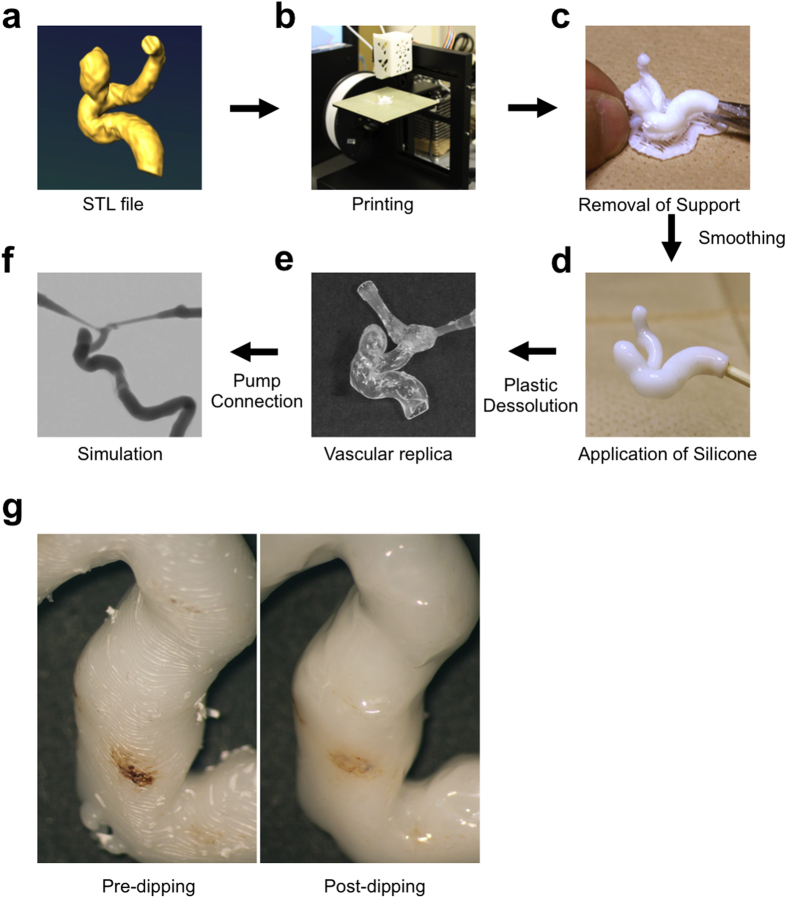

Figure 1. Manufacturing process of patient-specific vessel simulator.

(a) DICOM data is obtained by CT, MRA, or rotational angiography. The data is converted to an STL file. (b) The STL file is exported and the ABS vascular model is printed using the 3D printer. (c) The ABS solid model and supports are removed with nippers. The surface is smoothed by dipping into ABS solvent and then dried. (d) The solid ABS model is coated with liquid silicone. (e) The ABS is dissolved in acetone after the silicone solidifies. (f) The silicone vessel is connected to a circulation pump and the simulation is performed. (g) The surface of the ABS vessel model is smoothed by ABS solvent. Left: Before dipping in the ABS solvent, Right: After dipping in the ABS solvent.