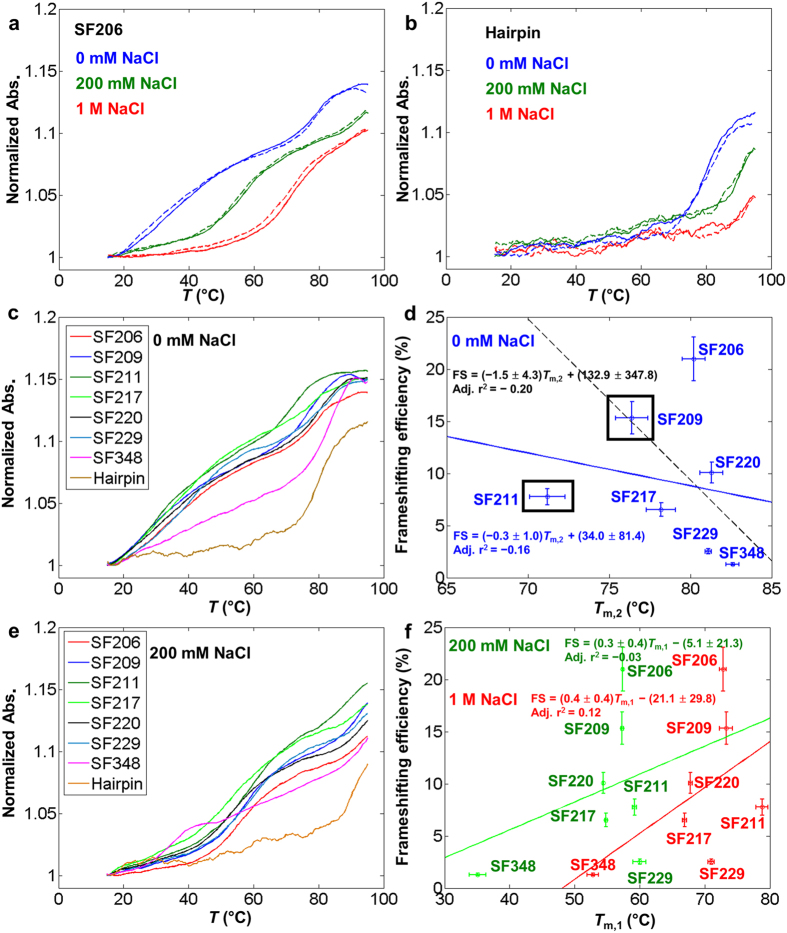

Figure 2. Ensemble thermal melting studies reveal no correlation between thermal stability and frameshifting efficiency.

Error bars for Tm,1, Tm,2 and frameshifting efficiency represent standard deviations. (a) Normalized UV melting trajectories of pseudoknot SF206 in the buffers with 1 M (red), 200 mM (green) and 0 mM (blue) NaCl, respectively. Solid lines represent the heating curve and dashed lines represent the cooling curve. (b) Normalized UV melting trajectories of isolated stem 1 hairpin (containing residues from 1–19) in the buffers with 1 M (red), 200 mM (green) and 0 mM (blue) NaCl, respectively. Solid lines represent the heating curve and dashed lines represent the cooling curve. (c) Normalized UV melting trajectories of pseudoknots and control hairpin in the buffer with 0 mM NaCl. SF348 shows only the melting of stem 1 suggesting that the pseudoknot structure for SF348 does not form at this condition. (d) No correlation is observed between Tm,2 in 0 mM NaCl and in vitro frameshifting efficiency previously measured19. The blue solid line and the black dashed lines represent the linear fitting curves for data points with and without SF209 and SF211 included, respectively. (e) Normalized UV melting trajectories of pseudoknots and control hairpin in the buffer with 200 mM NaCl. (f) No correlation is observed between Tm,1 value in 200 mM NaCl (green) and 1 M NaCl (red) and previously measured in vitro frameshifting efficiency19. The green and red lines represent the linear fitting curves for thermal melting data points obtained at 200 mM and 1 M NaCl, respectively.