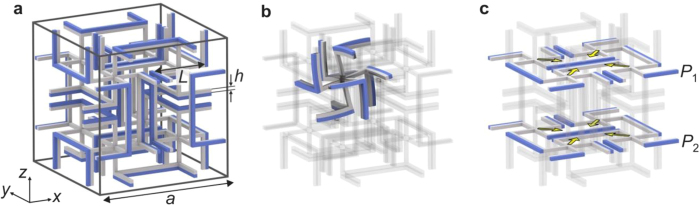

Figure 1. Illustration of the micro-lattice blueprint underlying our experiments.

(a) One unit cell of the three-dimensional lattice composed of two different constituent materials. The one shown in gray has a smaller positive thermal length-expansion coefficient than the one shown in blue. This unit cell is repeated on a simple-cubic translation lattice with lattice constant a. The distance between the 3D crosses is a/2. All beams have quadratic cross section with width h. Geometrical parameters: a = 100 μm, h = 2.5 μm, and L = 40 μm. (b) In one eighth of the unit cell, the calculated structure is exhibited for an increased temperature, assuming a linear response. For clarity, all changes are largely exaggerated. One obtains an expansion and bending of the bi-material beams. The bending leads to a rotation of the three-dimensional cross, resulting in an inward movement of this cross (negative thermal length-expansion coefficient). The other seven eighths of the unit cell behave as mirror images (with respect to the three principal Cartesian planes) of the eighth shown. (c) Same as panel a, but two planes P1 and P2 parallel to the xy-plane cutting through the three-dimensional crosses are highlighted. These planes are imaged by optical microscopy in the experiments shown in Fig. 3.