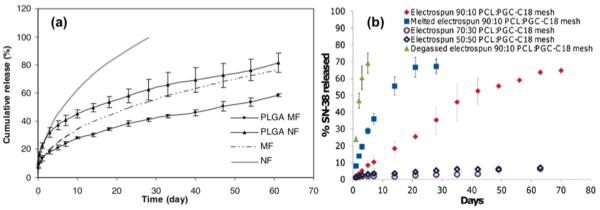

Fig. 1.

Examples of sustained release curves from electrospun uniaxial fibers: (a) 10 wt.% loaded paclitaxel in PLGA microfibers (PLGA MF) and nanofibers (PLGA NF) and first order release curve fitting for microfibers (MF) (k = 0.119, n = 0.45) and nanofibers (NF) (k = 0.223, n = 0.45). Release of paclitaxel sustained for 60 days to 80% cumulative release in PLGA NF and 60% cumulative release in PLGA MF. Fiber diameter significantly affected the release profile. [54]; (b) Release curves of SN-38, a bioactive agent, from blends of PCL and poly (glycerol monostearate-co-ε-caprolactone) (PGC-C18) at ratios of 90:10, 70:30, 50:50 PCL:PGC-C18. Effect of air displacement was minimal for the degassed 90:10 PCL:PGC-C18 mesh comparing to the native one. Melted mesh (at 80 °C for 1 min) reduced the pores and further eliminated time required for air displacement comparing to the native one. Higher PGC-C18 doping in the mesh significantly reduce the release rate. The effect on air displace has a direct influence on the wetting of the mesh and thus affects the release rate [40].