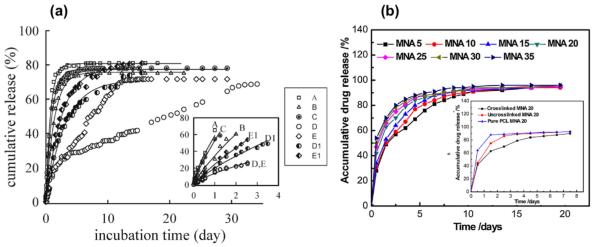

Fig. 2.

Examples of sustained release curves from electrospun coaxial fibers: (a) Cumulative release of DMOG from electrospun fibers. Figure legends: A (PLA), B (PHB), C (PLA-core PHB-shell; Qc/Qs = 0.5/1.5; drug in shell), D (PLA-core PHB-shell; Qc/Qs = 0.5/1.5; drug in core), E (PLA-core PHB-shell; Qc/Qs = 2.0/1.5; drug in core), D1 (PHB-core PLA-shell; Qc/Qs = 1.5/0.5; drug in core), E1 (PHB-core PLA-shell; Qc/Qs = 1.5/2.0; drug in core). Fiber type D showed a sustained release of 70% of DMOG over 30 days. Switching core and shell polymers resulted in burst release due to different hydrophobicity of PLA and PHB. Shell thickness of fiber type D is twice thicker than fiber type E resulting in significant effect in release rate. [71]; (b) Cumulative release of metronidazole (MNA) loaded from 5 wt.% to 35 wt.% in the core of PCL-core gelatin-shell fibers (all gelatin shells were cross-linked). Higher drug loading increased the release rate. Insert showed the release curves on the effect gelatin shell crosslinking. Crosslinking of the gelatin shell resulted in changes of hydrophobicity and therefore changing the release behavior [76].