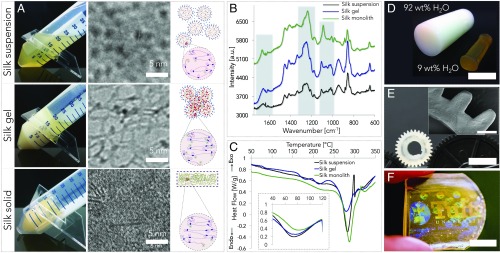

Fig. 1.

Formation of 3D silk fibroin constructs through an all-water process. During self-assembly, the protein undergoes polymorphic changes that encompass its nanostructure, molecular configuration, and bound water. (A) Macroscopic and nanoscopic investigation of the self-assembly process and relative schematic of the proposed mechanism. Cryo-electron micrographs obtained at different stages of silk fibroin self-assembly depicted that the protein possesses (i) micellar (or nanoparticle), (ii) nanofibrillar, and (iii) bulk structures when in suspension, gel, and solid forms, respectively. β-Sheets configurations are visible in the micrograph of solid silk. The presented images were cropped from the original EM micrographs to highlight—with comparable resolution—the morphological changes at the nanoscale of silk fibroin materials during the sol–gel–solid transition. (B) Micro-Raman spectroscopy showed the polymorphic nature of the protein, which is organized in random coil, helices, and β-sheets when in suspension, gel, and solid form, respectively. (C) DSC showed a decrease in free water (endothermic peak decrease and shift toward higher temperature in the Inset image), a more crystalline configuration (decreased endothermic peaks in T = 150–240 °C range that mark amorphous-to-crystalline reconfiguration of the protein secondary structure), and an increase in the thermal stability (shift toward higher temperature of the endothermic peak in the T = 250–300 °C range, which mark protein degradation) of silk fibroin as the self-assembly progresses. (D) Gel–solid transition of silk fibroin materials is due to the evaporation of the free water present in the gel structure and results in a quasi-homogeneous shrinkage of the material. Volume reduction varies from 72 to 90%, depending on the initial concentration of the protein in the gel. (E) By using the homogenous volume reduction of the material during the gel–solid transition, complex shapes (e.g., gears) of defined dimensions can be fabricated, starting from appositely fabricated molds, that take into account the percentage of volume reduction. (F) Soft lithography techniques may also be used to microstructure the surface of silk solid materials during the gel–solid transition. For example, by compressing (P = 100 kPa) one surface of the gel to a nanostructured material during the gel–solid transition it is possible to replicate (as a negative) the holographic pattern present on the master.