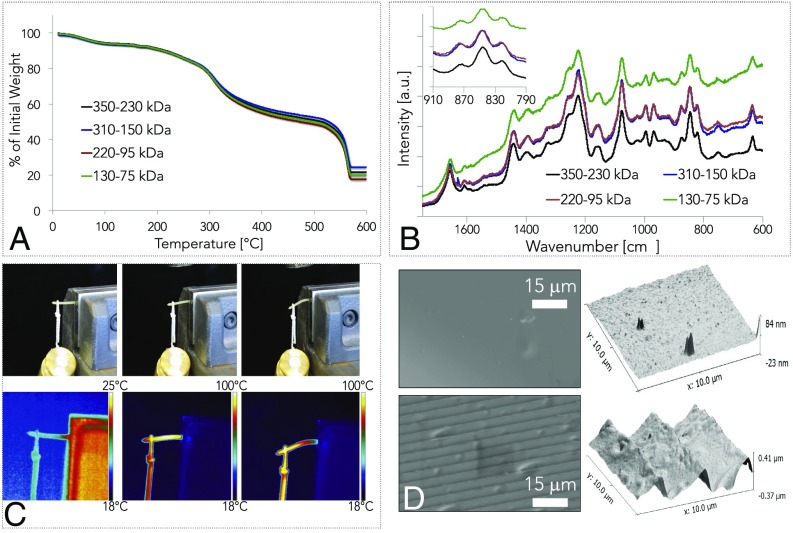

Fig. 2.

Thermoplasticity of silk fibroin constructs. The semicrystalline nature of silk fibroin and the presence of free and bound water in the protein structure impart partial thermoplasticity to the solid material. (A) Thermogravimetric analysis was used to study the interplay between silk fibroin molecular weight and the residual water present in the solid material. Thermogravimetric curves of silk fibroin show an increase in free and bound water for materials with higher molecular weight. (B) Micro-Raman spectroscopy was used to investigate the presence of structural water in silk solid materials, as a function of molecular weight. Although the spectra of the protein did not present significant differences in the Raman shift as a function of molecular weight, the study of I850/I830 ratio (Inset), which allows to study the hydrogen-bonding state of protein’s tyrosine phenoxyl group, depicted a more hydrophobic tyrosine environment (higher I850/I830 ratio) for higher protein molecular weights. (C) As a proof-of-concept of silk fibroin thermoplasticity, a dead load of 200 g has been applied to an end of a silk rod (Ø = 1 mm) that was secured at the opposite end with a bench vise. Thermograms of the experimental setup show that the increase of the rod internal temperature (heat was applied with a heat gun) above 80 °C causes a plastic deformation of the material. (D) Silk fibroin thermal reflow can also be used to imprint microstructures on the surface of the solid silk materials, by a combination of heat and pressure. For example, a diffraction grating can be imprinted on the surface of solid silk materials. Scanning electron micrographs and atomic force micrographs depicted the surface of a self-assembled silk fibroin construct before and after imprinting (60 °C, 60 s, 100 kPa) a periodic microstructure obtained from a diffraction grating. The material thermal reflow caused the formation of a grating structure on the surface of the silk fibroin construct.