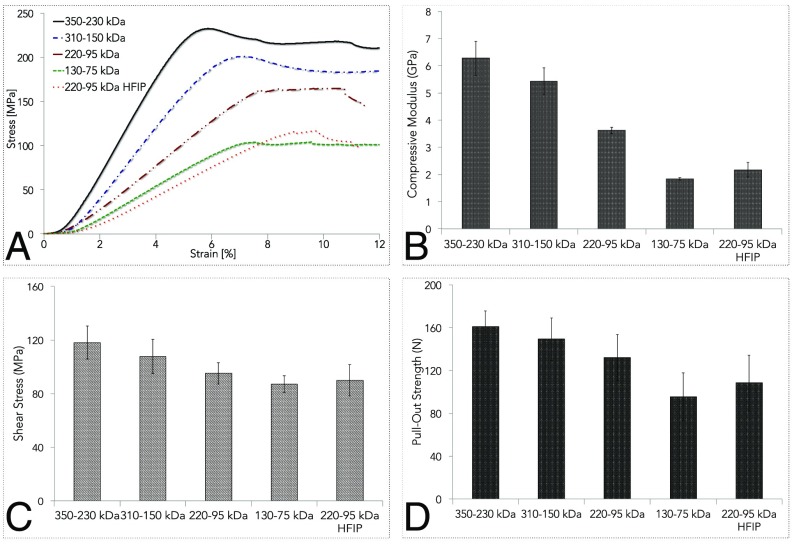

Fig. 3.

Mechanical properties of silk fibroin solid materials. Cylindrical specimens were assessed through compression tests to evaluate the mechanical properties of silk fibroin monoliths as a function of molecular weight. Cylindrical silk fibroin specimen obtained through a HFIP-based process was used as reference material. (A) Representative stress–strain curves of silk materials under uniaxial compression forces. (B) Compressive modulus of silk materials as a function of molecular weight. To silk fibroin materials with higher molecular weight corresponded an increase in the compressive modulus. (C) Four-point bending test was also performed to evaluate the flexural strength of silk fibroin bars. Higher values of shear stress at failure were measured at increasing silk fibroin molecular weights. (D) Cylindrical specimen of silk fibroin of different molecular weights were machined in screws. The pull-out strength from a bone phantom was evaluated to test the biomechanical behavior of the material at the interface with a mineralized tissue phantom. The higher the molecular weight of silk fibroin, the higher the strength required to pull the screw out of the bone phantom.