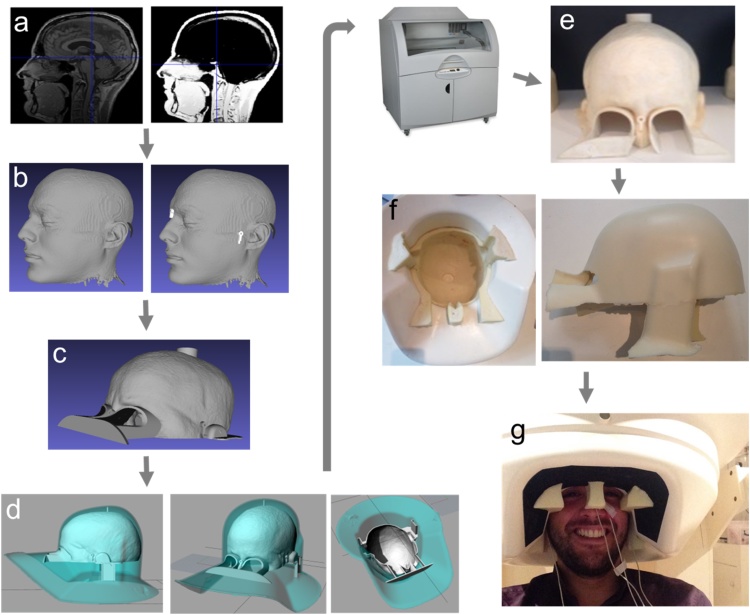

Fig. 1.

Overview of head-cast construction steps. a) Head surface is extracted from an anatomical MRI image using the standard SPM12 segmentation procedure. b) Head surface extraction is converted to a surface file and fiducial coils are added. The coil locations are defined in MRI coordinates. c) A positioning cylinder at the top of the head is added to the virtual model to define the position of the head inside the head-cast. Eye extensions are added to enable vision during use. d) Using and adjusting the positioning cylinder, eye extensions and ear extensions, the virtual head model is positioned appropriately inside a virtual copy of the MEG dewar. e) The positive head model is 3D printed. f) The 3D print is placed inside the manufacturer-provided dewar copy (as in d) and foam resin is poured in to fill the gap between the printed positive head model and the dewar. The fiducial coil protrusions on the 3D printed head result in coil-shaped and coil-sized indentations in the head-cast (the nasion coil protrusion is visible between the eyes in e). g) The subject can now wear the flexible foam head-cast and enter into the (real) MEG dewar for scanning.