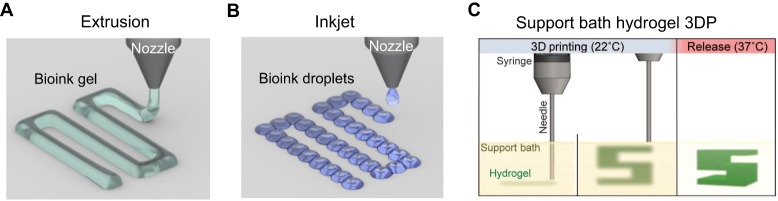

Fig. 4.

Material extrusion-based 3D bioprinting. (A) For extrusion-based bioprinting, material is selectively guided onto a platform via pressurized emission through a nozzle. The material, or ‘bioink’, is composed of an ECM-like biomaterial, cells and soluble factors. (B) For inkjet-based bioprinting, droplets of bioink are distributed across a surface to form a patterned layer. (C) For support bath hydrogel 3DP, biomaterial is extruded into a support hydrogel material. At 22°C, the hydrogel bath is stable enough to support the extruded print material, but at 37°C, the hydrogel bath transitions into a more liquid state to release the 3D printed object. The support bath allows formation of complex structures with overhanging regions such as the 3D ‘S’ structure, which is not possible with regular extrusion 3DP. Additionally, support bath hydrogel 3DP enables fabrication of structures without the need for layer-by-layer production; material can be extruded along any linear path within the enclosed gel bath volume. Reproduced with permission from Hinton et al. (2015).