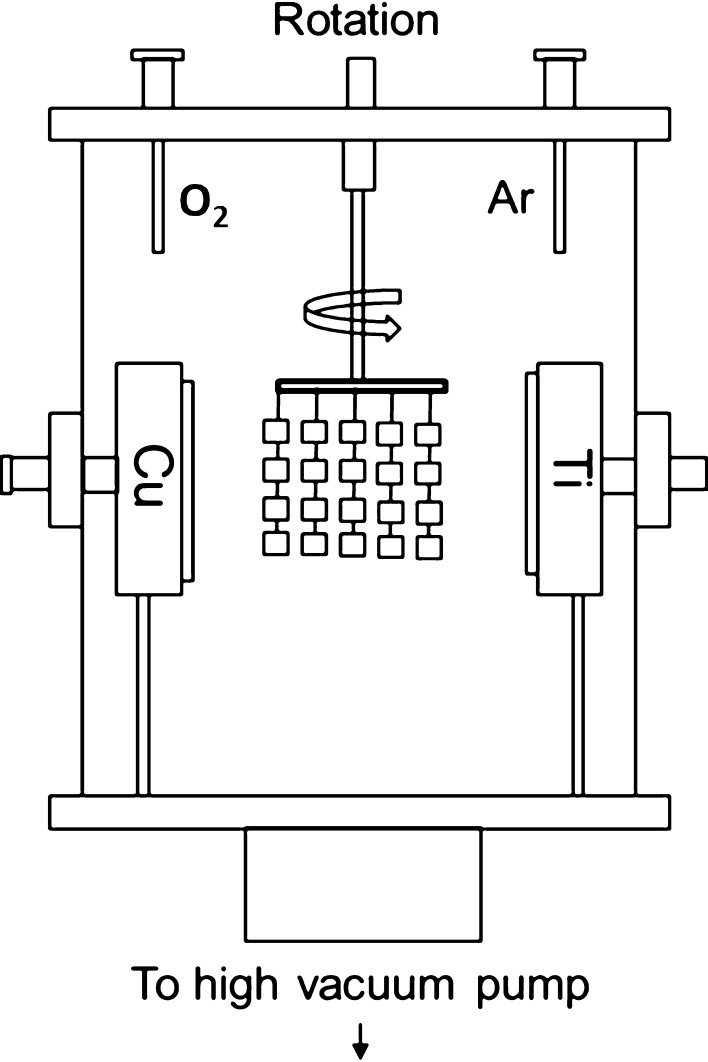

Fig. 1.

This schematic drawing shows the characteristics of the closed-field unbalanced magnetron sputtering system used for TiCuO coating depositions. This deposition system is a cubic chamber (30 inches × 30 inches × 30 inches) that contains two unbalanced magnetrons of reversed magnetic polarities installed vertically to form a closed magnetic field. The substrates were ultrasonically cleaned in acetone and ethyl alcohol for 10 minutes each. After cleaning, the substrates were installed in the deposition chamber on a double-rotation holder. Before all film depositions, a base negative pressure in the deposition system was achieved. The titanium target was powered by HiPIMS (HiPIMS Cyprium™ plasma generator; Zpulser Inc) and the copper target was powered by pulsed dc magnetron sputtering (Pinnacle plus; Advanced Energy Inc). Argon and oxygen gas flows were introduced into the system through ports in the side of the chamber. The chamber was baked to release adsorbed water and gasses at 120°C.