Abstract

Processing conditions are an important determinant of French fry quality. However, the effect of low-temperature long-time (LTLT) and high-temperature short-time (HTST) blanching and frying treatments has not been investigated in many cultivars. The current study investigates the effect of the sequential application of these treatments on French fries processed from six Irish potato cultivars (Fianna, Innovator, Mondial, Navigator, Panamera and Savanna). Blanching was effected at 75 °C for 10 min or 85 °C for 5 min and frying was effected at 160 °C for 2 min or 180 °C for 1 min. These treatments resulted in significant differences in the quality of the fries across the cultivars. The blanching treatments had a greater impact on the French fry quality than the frying treatments. LTLT blanching resulted in lower oil (12–13% fresh mass basis [fmb]), and higher protein (3.5–4.3% fmb) and mineral content in the French fries processed from Innovator, compared to HTST blanching. This was accompanied by a crispier crust, which required a greater puncture force (1.2–2.1 N) for penetration. Blanching with the LTLT treatment before HTST frying resulted in French fries that were the most acceptable to consumers and these were from Fianna, Innovator and Mondial. The current study demonstrates that the effect of French fry processing conditions is cultivar-dependent.

Keywords: Potato processing, French fries, Oiliness, Crispness, Nutrient content, Consumer acceptance

Introduction

The increasing awareness of the influence of food on human health has shifted consumer preferences to healthier foods (Aschemann-Witzel and Hamm 2010). This makes it necessary for French fry processors to prioritise preservation and even enhancement of the nutritional value during processing. Although the quality of French fries mainly depends on the cultivar processed, it is also affected by the processing conditions (Agblor and Scanlon 2000; O’Connor et al. 2001; Elmore et al. 2015; Yang et al. 2016). Industrial processing of French fries usually involves the sequential application of hot water treatment (blanching), hot air drying and partial deep fat frying, before French fry strips are cooled, frozen and packaged for final processing. Blanching is mainly aimed at inactivating enzymes responsible for browning (polyphenol oxidase and peroxidase) and lowering the reducing sugar content of the raw potatoes (Mestdagh et al. 2008; Yu et al. 2010; Mariotti et al. 2015). The process also promotes gelatinisation of starch, and subsequent moisture reduction through the partial drying and frying steps. However, blanching is responsible for some of the nutrient losses that occur during French fry processing (Arroqui et al. 2002; Haase and Weber 2003; Jimenez et al. 2015). Furthermore, the deep fat frying operation ensures rapid cooking and the development of a unique flavour and other sensory properties, which is largely associated with oil uptake. The final oil content of French fries raises consumer health concerns. Variants of the blanching and frying techniques, such as infrared dry blanching and vacuum frying, have been explored, to limit nutrient loss and oil absorption in French fries (Bingol et al. 2012, 2014; Pedreschi 2012; Teruel et al. 2015). However, such applications have not been commercialised due to implementation complexity and higher financial investment requirements, compared to traditional processing methods. With technological and economic feasibility taken into consideration, finding a good balance between the temperature and time for blanching and frying is the simplest way of influencing product quality on an industrial scale.

The application of a low-temperature long-time (LTLT) blanching treatment, at 55–75 °C for 10–60 min, has been shown to improve the quality of French fries (Aguilar et al. 1997; Pedreschi et al. 2008). However, Mestdagh et al. (2008) reported that blanching French fry strips at higher temperatures (i.e. 70–80 °C) was more effective at reducing the levels of reducing sugars relative to blanching at lower temperatures. Reducing sugars increase the potential for acrylamide formation, which is not desirable. These studies also demonstrated that blanching temperature was the main factor affecting the potential for acrylamide formation rather than blanching time. On the other hand, low frying temperatures have been reported to result in higher oil uptake, compared with high frying temperatures (Moyano and Pedreschi 2006). Studies investigating the frying parameters for French fries also highlight temperature as the main factor influencing French fry quality, rather than time (Liu and Scanlon 2007; Mestdagh et al. 2008; Millin et al. 2016). However, the effect of LTLT and HTST blanching and frying treatments and their sequential application is not known for many cultivars. The application of LTLT and HTST blanching and frying treatments has been contrasted by Agblor and Scanlon (2000) on the well-known French fry cultivars, Russert Burbank and Shepody. That study showed that HTST blanching (97 °C for 2 min) and frying (182 °C for 1.5 min) produced fries with a lower crust hardness, whilst LTLT blanching (70 °C for 10 min) and frying (166 °C for 3.5 min) produced the opposite result. van Loon et al. (2007) tested the effect of different partial-frying time and temperature combinations, which included LTLT and HTST treatments, on the cultivar, Agria, and reported that HTST partial-frying (180 °C for 1.9–2.2 min) resulted in a crispier product, compared with LTLT partial-frying (160 °C for 1.4–1.6 min). Since the physicochemical characteristics of potatoes change with genotype, the present contribution focuses on describing the effect of the selected blanching and frying treatments on five other cultivars, which have not been delineated for French fry processing, together with a known French fry cultivar. The six cultivars evaluated were selected based on the countrywide (South Africa) availability of seed tubers at the time of the investigation. The five non-delineated cultivars, altogether, represented those that are popular and those that have recently been introduced in the local potato industry. The objective of the study is to compare the sequential application of LTLT and HTST blanching and frying treatments on the nutritional and sensory quality of the respective cultivars. This is done to evaluate their suitability for French fry processing, and to make recommendations for suitable processing methods.

Materials and methods

Irish potatoes (Solanum tuberosum L.) of the cultivars, Fianna, Innovator, Mondial, Navigator, Panamera and Savanna, were produced at the Ukulinga Research Farm, of the University of KwaZulu-Natal, Pietermaritzburg, South Africa (30°24′E, 29°40′S). This was under the same cultivation conditions, with irrigation, during the 2014/15 production season (summer). Potatoes were manually harvested in March 2015 and stored in nylon mesh bags in a temperature-controlled room (8–12 °C; relative humidity >75%), in the dark, for up to 2 months. Of the six cultivars, Innovator is used for industrial French fry processing, Mondial is popular and the other cultivars are new in the South African potato industry. A factorial design with six cultivars, two blanching treatments and two frying temperatures was used.

French fry processing

Potatoes were retrieved from storage, allowed to acclimate to an ambient temperature (±25 °C) over-night and peeled using a 12 kg electric potato peeler (Anvil, South Africa). Peeled potatoes were cut into 10 mm × 10 mm strips with a manual French fry chipper and rinsed in tap water. Batches of the strips (1.5 kg each batch) were blanched in a two litre water bath either at 75 °C for 10 min (LTLT blanching) or at 85 °C for 5 min (HTST blanching). Water was drained by transferring strips into a stainless steel sieve, then the strips were partially dried in a convection oven at 85 °C for 10 min (Pedreschi et al. 2008). The strips were partially fried in commercial canola oil (density = 0.89 g cm3, at an ambient temperature), in a deep fat fryer either at 160 °C for 2 min (LTLT frying) or 180 °C for 1 min (HTST frying), in a 1:10 (w/v) potato to oil ratio (van Loon et al. 2007). For each cultivar, the oil of each of the two frying treatments was changed (replaced with fresh oil) after frying triplicate samples of each of the two blanching treatments (i.e. six samples of each cultivar were fried before changing the oil). The weight of each blanched sample to be fried was 1 kg. The oil was replenished after frying each sample. Oil deterioration was monitored by measuring the total polar compounds using a Testo 270 deep-frying oil tester (Testo Inc., Germany), which did not exceed 11% at the point of discard. Immediately after frying, strips were placed in a glass tray lined with paper towel, to drain excess oil until they cooled to an ambient temperature, packaged in freezer bags (Glad, China) and freeze-stored at −20 °C until required for quality assessments. After storage, French fries were retrieved and their frying completed in the same conditions as for partial frying. French fries were allowed to cool to room temperature and then analysed for moisture content and consumer acceptance as described below. The rest of the fries were packed back into freezer bags and stored in a freezer until required for other chemical analyses.

Chemical analyses

Moisture content

Three randomly selected French fries were weighed before and after oven-drying at 105 °C to a constant weight (Mariotti et al. 2015). Moisture content was calculated and expressed as the percentage of weight lost during oven-drying.

Oil content

Randomly selected frozen French fries were lyophilised (at −56 °C, 4.0 mbar) for 72 h, using a VirTis BenchTop ‘K’ series freeze dryer (SP Industries, USA), and ground with an electric coffee bean grinder (Mellerware, South Africa). The samples were stored in air-tight plastic bags at an ambient temperature, up to a week, before analysis. Oil content was determined in triplicate from the ground samples. Two g sample aliquots were mixed with 4 g anhydrous Na2SO4 and 10 ml hexane, swirled for 1 min and left to stand in a fume hood at an ambient temperature for 5 min (Csallany et al. 2015). The hexane supernatant was decanted into a pre-weighed glass scintillation vial and extraction was repeated on the sediment, twice more, with 10 ml of hexane. The hexane portions were combined and the hexane evaporated using a GenVac EZ-2 evaporator (Ipswich, UK). The oil extracted was weighed and expressed as a percentage on a fresh mass basis (fmb).

Crude protein content

Frozen French fries were dried at 75 °C overnight and milled with an SM 300 milling machine (Retsch, Germany), to prepare three 0.5 g dry samples. Crude protein content was determined using the automated Dumas dry combustion method (Bárta and Bártová 2008). The 0.5 g samples were placed in ceramic crucibles, into which 0.5 g of vanadium pentoxide was added as a combustion catalyst. This was burnt in a stream of oxygen at 1350 °C in a horizontal furnace of a LECO CNS 2000 Elemental Analyzer (LECO Corporation, USA). Nitrogen was determined (as N2) in a thermal conductivity cell, against an Alfalfa standard (LECO Africa, South Africa). The crude protein content was calculated by multiplying total weight of nitrogen by a conversion factor of 6.25 and expressed as a percentage on a fmb.

Mineral content

Mineral element content was determined, in triplicate, from frozen French fry samples. French fries were dried at 105 °C for 2 h and milled with the SM 300 milling machine, to obtain a 0.5 g sample. This was burnt to ash in a furnace overnight at 450 °C and placed in a 100 ml pre-weighed glass beaker. The ash was moistened with a few drops of deionised water before adding 2 ml of HCI (32%). The sample was placed in a boiling water bath in a fume hood to ensure thorough dryness through evaporation. A 25 ml solution made from HCl and deionised water (ratio 1:9) was added. The sample was stirred and filtered using Whatman’s No. 1 filter paper. The filtrate was diluted with deionised water to a 1:5 dilution ratio and analysed for phosphorous (P), potassium (K), calcium (Ca), magnesium (Mg), sodium (Na), zinc (Zn), copper (Cu), manganese (Mn), iron (Fe) and aluminium (Al) using an inductively coupled plasma optical emission spectrometer Vista-MPX 2004 (Varian, Australia). Analysis was done against known standard solutions of the elements (Separations, South Africa) and a blank (deionised water). The mineral element content was expressed as mg 100 g−1 fresh mass.

Physical analyses

Colour

Three randomly selected French fries were assessed at three points along the length of each French fry using a Chroma Meter CR-400 (Konica Minolta, Japan) to obtain the mean Hunter L*, a* and b* colour coordinates. The Hunter Lab colour system uses L* as a measure of lightness (0 = black to 100 = white), a* as a measure of redness and (+a* = redness; −a* = greenness), and b* as a measure of yellowness (+b* = yellowness; −b* = blueness).

Crust hardness

Crust puncture assessments were done using the Instron 3345 Universal Testing Machine (High Wycombe, England) with the Instron Bluehill 2 Version 2.25 software. A 1.5 mm diameter cylindrical probe was used to puncture three holes at three points along the length of a French fry, at a test speed of 1 mm s−1, at an ambient temperature (±25 °C). Penetration was to the depth of 2 mm (Al-Khusaibi et al. 2015). This gives an indication of the maximum shear force (N) required to puncture the fries (i.e. overall hardness of the crust).

Sensory evaluation

Fry sensory acceptability in terms of taste, oiliness and overall acceptability was measured by sixty untrained panellists using a 9-point hedonic rating scale to determine consumer acceptance of the products (1 = dislike extremely, 5 = neutral and 9 = like extremely). Only the use of one-digit scores was permitted. Ethical approval to conduct this assessment was obtained from the University of KwaZulu-Natal, Humanities and Social Sciences Research Ethics Committee (reference number HSS/0871/015D) before panellists, from the university community, were recruited for participation. The panellists were students and staff, of age ranging from 16 to 55 years. Samples were blind labelled with three-digit numbers obtained from The Table of Random Numbers and served in random order determined from the Table of Random Permutations of Nine. Panellists were provided with an evaluation questionnaire to rate the taste, oiliness and overall acceptability of the coded samples (Lloyd et al. 2004). Bottled spring water was provided for the panellists to rinse their palates between samples.

Data analysis

Results were analysed using GenStat for Windows (17th edition; VSN International, United Kingdom). The general Analysis of Variance was used to test for differences and interaction between parameters. Duncan’s multiple comparisons test was used to separate means at the 95% probability level. Pearson’s correlation analysis was performed to determine the relationships between parameters.

Results and discussion

Chemical composition of the French fries

Moisture content

Figure 1a shows that French fry moisture content significantly (P < 0.01) differed among cultivars, but the differences resulting from the blanching and frying treatments tested were not significant (P > 0.05). The two-way interaction between cultivar and blanching treatment was significant (P < 0.01), while that between cultivar and frying treatment and the three-way interaction between all three factors (cultivar, blanching and frying treatments) were not significant (P > 0.05). As it can be seen in Fig. 1a, French fries of Savanna generally had the highest moisture content (54–57%), while those of Fianna and Innovator had the lowest (≤46%). Those of Fianna had a significantly lower moisture content than those of Savanna, regardless of the processing treatments used. Using the moisture content of French fries, the cultivars could be described in the following order: Savanna > Navigator > Mondial > Panamera > Innovator > Fianna. The results reported in this study were within the range of moisture contents reported by Sanz et al. (2007), for industrial fries. The relative differences in the moisture content of French fries from the six cultivars were reflective of the differences that existed in raw potatoes (data not shown), as moisture loss is proportional to the moisture content of raw material (Pedreschi 2012). French fries processed from Innovator had the largest difference in moisture content (29–30%) when blanching was effected through the HTST treatment, compared with LTLT blanching, regardless of the frying treatment applied after blanching. In this case, HTST-blanched French fries had a lower moisture content (32%) than LTLT-blanched fries (45–46%). This trend was not evident in French fries processed from the other cultivars. Notably, the moisture content of the French fries processed from Innovator that had been HTST-blanched before frying was significantly lower than that of the other cultivars processed using the same treatments, except those of Fianna. The lack of statistical differences in the moisture content of French fries resulting from the main effects of the blanching and frying treatments in the other cultivars could be attributed to the overriding differences in the raw material due to genotype. This could also be attributed to the narrow differences in the time and temperature treatment combinations that were applied. However, the moisture content of French fries has been shown to typically decrease when frying times and temperatures are increased independently in other studies (Pedreschi and Moyano 2005; Bingol et al. 2012).

Fig. 1.

Moisture (a), oil (b) and protein (c) content of French after processing. LTLT low-temperature long-time (75 °C for 10 min for blanching and 160 °C for 2 min for frying), HTST high-temperature short-time (85 °C for 5 min for blanching and 180 °C for 1 min for frying). Bars with the same letter differ non-significantly (P > 0.05)

Oil content

Figure 1b shows that the oil content of the French fries significantly (P < 0.01) differed among cultivars and between the blanching and frying treatments tested. Just like with moisture content, a significant (P < 0.001) two-way interaction between cultivar and blanching treatment, and a three-way interaction among the three factors tested were detected. However, no other interactions were significant (P > 0.05). As it can be seen in Fig. 1b, the French fries processed from Savanna generally had the lowest oil content (8–10%), while those of Innovator, that had been subjected to HTST blanching before frying, had the highest oil content (19–31%). The differences in the oil content of French fries from the cultivars can be attributed to a negative correlation (r = −0.75) between the moisture and oil content of fries analysed in the present study. The inverse relationship between the moisture and oil content of fries has also been reported by Bingol et al. (2012), and is a reflection of a similar relationship between the moisture content of raw potatoes and the oil content of fries (Krokida et al. 2001; van Loon et al. 2007). This is because oil enters potatoes through a water replacement mechanism, which involves changes in cellular structures and the formation of pores during frying, to fill some of the spaces created by induced dehydration (Saguy and Dana 2003).

In agreement with the results of the present study, other studies have shown that blanching, when succeeded by frying, has a significant effect on the oil absorption capacity of potatoes. Two independent studies have shown that French fry strips blanched with the HTST (97 °C for 2 min) treatment absorb more oil (Pedreschi et al. 2005), and LTLT-blanched (55–70 °C for 15–60 min) fries absorb less oil (Mestdagh et al. 2008), compared with non-blanched strips. This is because blanching involves the combined application of heat and water, which gelatinises the starch on the surface of potato strips. In the present study, the direction of the change of the oil content, in response to the blanching and frying treatments tested, was not consistent among cultivars (Fig. 1b). French fries processed from Innovator, had the largest difference in oil content (≥37%) when blanching was effected through the HTST treatment, compared with the LTLT treatment, regardless of the frying treatment applied after blanching. In this case, HTST-blanched French fries had a higher oil content (19–21%) than LTLT-blanched fries (12%). This was also evident in French fries processed from Savanna and Panamera, but not in French fries processed from other cultivars (Fig. 1b). In the literature, there is a lack of studies which contrast the oil content of French fries made from strips blanched with the two blanching treatments investigated in the present study.

Crude protein content

Figure 1c shows that, as with oil content, the protein content of French fries significantly (P < 0.01) differed among cultivars and between the blanching and frying treatments tested. All interactions between the factors were significant (P < 0.01). There was a positive correlation (r = 0.70) between the protein and moisture content of fries. Furthermore, French fry protein content was negatively correlated to oil content (r = −0.74). The direction of the change of the protein content, in response to the blanching and frying treatments tested, was not consistent among cultivars. As can be seen in Fig. 1c, French fries processed from Innovator that had been subjected to HTST blanching before frying, had the lowest protein content (2.2%). As with oil content, French fries processed from Innovator showed the largest difference in protein content (≥37%) when blanching was effected through HTST blanching (2.2%), compared with LTLT blanching (3.5 and 4.3%), regardless of the frying treatment applied after blanching. This is thought to be due to the leaching of proteins during the blanching process, as also reported by Bognàr (1998) for boiled potatoes. Bognàr (1998) showed that deep fat frying potatoes resulted in a higher protein retention than boiling. In the present study, French fries processed from Innovator that had been subjected to LTLT blanching before frying with the HTST treatment had the highest protein content (4.3%).

Mineral content

The mineral content of the French fries produced in the present study (P, K, Ca, Mg, Na, Zn, Cu, Mn, Fe and Al) significantly (P < 0.001) differed among cultivars. Generally, the mineral content of the French fries significantly (P < 0.05) differed with the processing treatments (Fig. 2). However, the blanching treatments tested non-significantly affected the K and Zn contents, and the frying treatments non-significantly affected the Ca, Cu and Mn contents (Fig. 2b, c, f, g, h). HTST blanching followed by frying resulted in considerable decreases in the mineral content of French fries processed from Innovator. This was attributed to the leaching of nutrients during the blanching step (Bognàr 1998), which was exacerbated by an increase in blanching temperature. While nutrient leaching is a disadvantage in terms of the dietary contribution for most elements, it is an advantage in the case of Na and Al, as a high consumption of these minerals has negative implications on human health (Aguilar et al. 2008). The results from the present study are in agreement with those reported by Arroqui et al. (2002), Haase and Weber (2003) and Jimenez et al. (2015), who showed that the blanching operation is responsible for most of the ascorbic acid lost during French fry processing. The present study further indicates that the nutrient losses are severe if blanching is done through the HTST treatment, instead of the LTLT treatment. Such an effect is suggestive of temperature enhancing the leaching of minerals from the potato tissues. This was supported by the detection of a positive correlation between the content of a number of the mineral elements assessed in the present study, i.e. P, K, Ca, Mg, Cu and Mn, and the moisture and the protein content in the fries (r > 0.50).

Fig. 2.

Mineral element (P [a], K [b], Ca [c], Mg [d], Na [e], Zn [f], Cu [g], Mn [h], Fe [i] and Al [j]) content of French fries after processing. LTLT low-temperature long-time (75 °C for 10 min for blanching and 160 °C for 2 min for frying), HTST high-temperature short-time (85 °C for 5 min for blanching and 180 °C for 1 min for frying). Bars with the same letter differ non-significantly (P > 0.05)

Physical properties of the French fries

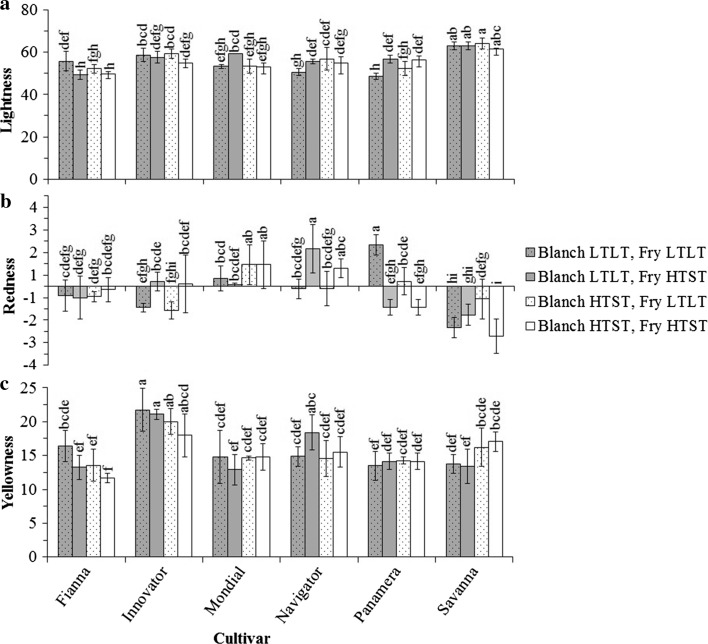

Colour

The lightness of French fries significantly (P < 0.001) differed among cultivars, but the differences between the blanching and frying treatments tested were not significant (P > 0.05). The differences among cultivars were evident in French fries processed using the same treatments (Fig. 3). There was a significant (P ≤ 0.01) two-way interaction between cultivar and the frying treatments and between the blanching and frying treatments. All the other interactions between factors were not significant (P > 0.05). Figure 3a shows that French fries processed from Savanna were generally the lightest, while those processed from Fianna were the least light, except those that had been subjected to LTLT blanching and frying. Using the lightness coordinates obtained from the Chroma Meter, the cultivars can be described in the following order: Savanna > Innovator > Mondial > Navigator > Panamera > Fianna. These results are an objective way of comparing the quality of French fries, as French fry lightness is known to be negatively correlated to the acrylamide content—a probable human carcinogen (Yang et al. 2016). Based on these findings, it can be deduced that French fries of Savanna had the lowest concentration of acrylamide than all the other cultivars and that those processed from Fianna had the highest acrylamide content.

Fig. 3.

Colour of French fries, in terms of a lightness, b redness and c yellowness, after processing. LTLT low-temperature long-time (75 °C for 10 min for blanching and 160 °C for 2 min for frying), HTST high-temperature short-time (85 °C for 5 min for blanching and 180 °C for 1 min for frying). Bars with the same letter differ non-significantly (P > 0.05)

This conjecture is also supported by the results on the redness of the fries (Fig. 3b), which show that French fries processed from Savanna were the least red. Redness has been shown to be positively correlated to the acrylamide content (Pedreschi et al. 2005). Moreover, Innovator resulted in the yellowest fries, and Fianna produced the least yellow fries (Fig. 3c). While the lightest fries are ideal to limit the consumption of acrylamide, a bright golden brown colour is desired in the product, and this corresponds to colours 1 and 2 on the USDA colour standards for French fried potatoes (USDA 2007). The fries produced in the present study were within this range, however, those processed from Savanna were far lighter and corresponded to colour 0 (Fig. 4). French fries processed from Innovator, Fianna and Panamera corresponded to colour 1 and those of Navigator and Mondial corresponded to colour 2 (Fig. 4).

Fig. 4.

French fries after processing with the LTLT blanching and frying treatment. Rows show three randomly selected strips from of the same cultivar. LTLT low-temperature long-time (75 °C for 10 min for blanching and 160 °C for 2 min for frying), HTST high-temperature short-time (85 °C for 5 min for blanching and 180 °C for 1 min for frying)

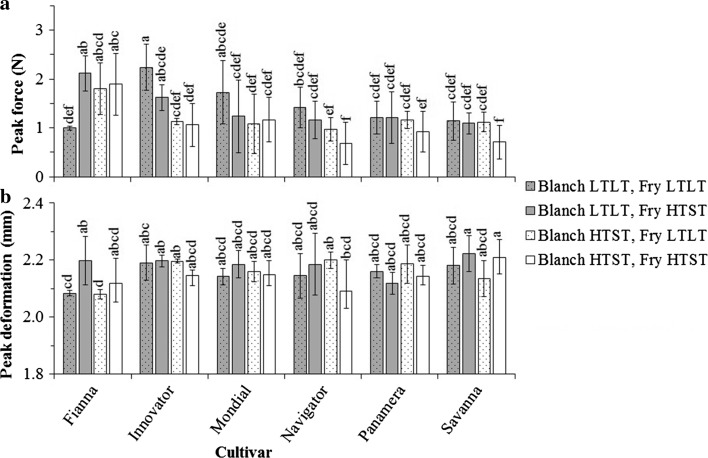

Crust hardness

The force required to penetrate the crust of French fries significantly (P < 0.01) differed among cultivars and between the blanching treatments tested, but the differences arising from the frying treatments were not significant (P > 0.05). Only the two-way interaction between cultivar and the blanching treatments was found to be significant (P < 0.05) on the crust hardness of French fries. All other interactions were not significant (P > 0.05). The peak force detected in samples ranged from 0.68 to 2.2 N (Fig. 5a). French fries processed from Innovator that had been subjected to LTLT blanching and frying were the hardest, and these were followed by those processed from Fianna that had been subjected to LTLT blanching before frying with the HTST treatment. Fries of Savanna were generally the softest. French fries blanched with the LTLT treatment were the hardest for most cultivars, except those processed from Fianna. This trend indicates that HTST blanching results in decreased crispness. This is in agreement with the findings of Agblor and Scanlon (2000) and Kita and Lisińska (2005), who showed that LTLT blanching improves French fry textural quality. Decreased crust hardness results from processes such as starch gelatinisation and sugar caramelisation, which become prominent at the temperature used for HTST blanching in this study (Aguilera et al. 2001; Liu and Scanlon 2007; Mestdagh et al. 2008). Starch gelatinisation and sugar caramelisation promote tissue softening and the development of a rubbery texture. The non-significance of differences in French fries produced from the frying treatments tested in this study was consistent with observations by van Koerten et al. (2015). Those authors showed that differences in French fry hardness were not significant when frying was tested at temperatures within the 150–180 °C range and time varied for up to two min.

Fig. 5.

Peak force (a) and deformation (b) of the French fries crust after processing. LTLT low-temperature long-time (75 °C for 10 min for blanching and 160 °C for 2 min for frying), HTST high-temperature short-time (85 °C for 5 min for blanching and 180 °C for 1 min for frying). Bars with the same letter differ non-significantly (P > 0.05)

However, that study revealed that crust hardness significantly decreases when frying was done at 195 °C. Teruel et al. (2015) further showed that larger variations in frying time (≥5 min) resulted in significant changes in crust hardness because the crust tends to thicken and become harder at high temperatures. In the present study, no consistent trends were detected in the deformation of French fries between the blanching and frying treatments tested (Fig. 5b). This was considered to be mainly due to the confounding differences in the potatoes processed arising from genotypic differences. However, peak deformation differences among cultivars were significant (P < 0.05). French fries processed from Fianna that had been subjected to LTLT blanching and frying had the least deformation, while those processed from Savanna that had been fried with the HTST treatment after blanching had the most deformation (Fig. 5b).

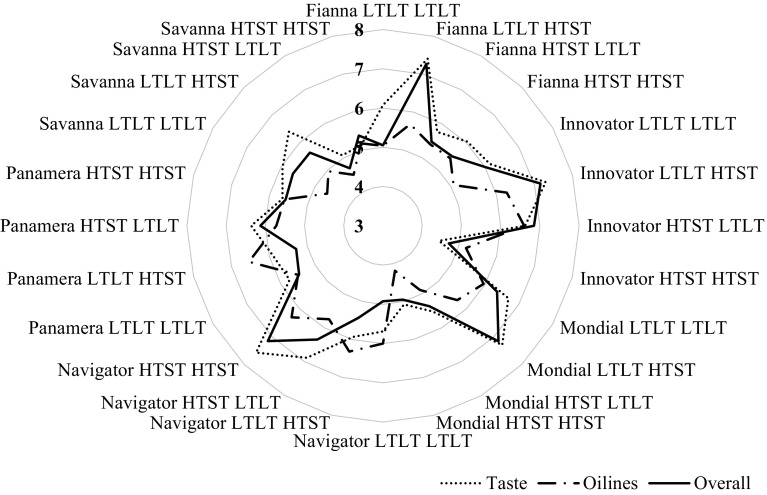

Consumer acceptance of the French fries

Figure 6 shows consumer acceptability of the French fries from all the treatment combinations tested in the present study. The ratings given by the panellists regarding the taste, oiliness and overall acceptability of French fry samples significantly (P < 0.05) differed among cultivars and between the blanching treatments.

Fig. 6.

Taste, oiliness and overall acceptability of French fries after processing. Labels indicate the name of the cultivar, the blanching treatment and the frying treatment applied, respectively. LTLT low-temperature long-time and HTST high-temperature short-time. For blanching: LTLT = 75 °C for 10 min and HTST = 85 °C for 5 min. For frying: LTLT = 160 °C for 2 min and HTST = 180 °C for 1 min. Graph shows the mean score given by consumers (n = 60) using a 9-point hedonic scale (1 = dislike extremely, 5 = neutral and 9 = like extremely)

However, differences in the ratings arising from the frying treatments were not significant (P > 0.05). Furthermore, all the interactions between cultivar, the blanching treatments and the frying treatments significantly (P > 0.05) affected the acceptability scores. This result made the selection of a suitable processing protocol cultivar-dependent. In terms of taste and overall acceptability, French fries processed from Fianna, Innovator and Mondial that had been subjected to LTLT blanching before frying with the HTST treatment were the most acceptable to the panellists (acceptability score >7) (Fig. 6). In addition, French fries processed from Navigator that had been subjected to HTST blanching and frying were acceptable on a similar degree (acceptability scores for taste and overall acceptability >7). For French fries processed from Panamera, HTST blanching followed by LTLT frying was the best treatment combination, which received an acceptability score >6. For Savanna, French fries that had been subjected to LTLT blanching and frying were the most acceptable (acceptability score >6). It was noted that the French fries produced in the present study, in most cases, had lower scores for oiliness acceptability than for taste and overall acceptability (Fig. 6). Panellists disliked the oiliness of French fries processed from Savanna the most, along with those of Mondial that had been subjected to HTST blanching before frying (acceptability score <5). Considering that the oil quantification analysis showed that these fries had the highest moisture and the lowest oil content than the fries from other cultivars (Fig. 1b), the dislike of fries from Savanna and Mondial that had been subjected to HTST blanching before frying is attributed to consumers preferring French fries that are moderately oily. Although, by quantification, the French fries processed from Innovator that had been subjected to HTST blanching before frying had the highest oil content (Fig. 1b), those that were subjected to LTLT frying after blanching had the most acceptable oiliness (acceptability score >6) (Fig. 6). French fries processed from Innovator that had been subjected to HTST blanching and frying, and those of Savanna that had been subjected to LTLT blanching before frying with the HTST treatment, were the only products that were not acceptable to panellist (overall acceptability score <5).

Conclusion

The results from this study indicate that the LTLT and HTST blanching and frying treatments tested have significant effects on the physical and sensory quality of French fries. However, the treatments tested did not affect the moisture and colour of the French fries. The effect of LTLT and HTST blanching and frying differed across cultivars, due to differences in the raw material attributed to genotype. This demonstrated the overriding effect of genotype on the French fry quality and indicated that selection of a suitable processing protocol should be done on a cultivar basis. In addition, the study showed that the blanching treatments had a greater impact on the French fry quality than the frying treatments. LTLT blanching and HTST frying were the best procedures for processing French fries from Fianna, Innovator and Mondial between the treatments tested. LTLT blanching particularly resulted in better mineral element retention in French fries, especially those processed from Innovator, compared with HTST blanching.

Acknowledgements

The authors are grateful to the South African National Research Foundation and the University of KwaZulu-Natal for their financial support.

Authors’ contribution

T. S. Workneh supervised the whole study and edited the manuscript. M. Siwela supervised the sensory evaluation assessments and edited the manuscript. N. Z. Ngobese conceived and conducted the experiments, analysed data and drafted the manuscript.

References

- Agblor A, Scanlon MG. Processing conditions influencing the physical properties of French fries potatoes. Potato Res. 2000;43:163–178. doi: 10.1007/BF02357957. [DOI] [Google Scholar]

- Aguilar CN, Anzaldúa-Morales A, Talamás R, Gastelum G. Low-temperature blanch improves textural quality of French-fries. J Food Sci. 1997;62(3):568–571. doi: 10.1111/j.1365-2621.1997.tb04432.x. [DOI] [Google Scholar]

- Aguilar F, Autrup H, Barlow S, Castle L, Crebelli R, Dekant W, Engel K-H, Gontard N, Gott D, Grilli S, Gürtler R, Larsen J-C, Leclercq C, Leblanc J-C, Malcata F-X, Mennes W, Milana M-R, Pratt I, Rietjens I, Tobback P, Toldrá F. Safety of aluminium from dietary intake [1]: scientific opinion of the panel on food additives, flavourings, processing aids and food contact materials (AFC) EFSA J. 2008;754:1–34. doi: 10.2903/j.efsa.2008.754. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aguilera JM, Cadoche L, López C, Gutierrez G. Microstructural changes of potato cells and starch granules heated in oil. Food Res Int. 2001;34:939–947. doi: 10.1016/S0963-9969(01)00118-1. [DOI] [Google Scholar]

- Al-Khusaibi M, Tarmizi AHA, Niranjan K. On the possibility of nonfat frying using molten glucose. J Food Sci. 2015;80:E66–E72. doi: 10.1111/1750-3841.12713. [DOI] [PubMed] [Google Scholar]

- Arroqui C, Rumsey TR, López A, Virseda P. Losses by diffusion of ascorbic acid during recycled water blanching of potato tissue. J Food Eng. 2002;52:25–30. doi: 10.1016/S0260-8774(01)00081-4. [DOI] [Google Scholar]

- Aschemann-Witzel J, Hamm U. Do consumers prefer foods with nutrition and health claims? Results of a purchase simulation. J Mark Commun. 2010;16:47–58. doi: 10.1080/13527260903342746. [DOI] [Google Scholar]

- Bárta J, Bártová V. Patatin, the major protein of potato (Solanum tuberosum L.) tubers, and its occurrence as genotype effects: processing versus table potatoes. Czech J Food Sci. 2008;26(5):347–359. [Google Scholar]

- Bingol G, Zhang A, Pan Z, McHugh TH. Producing lower-calorie deep fat fried French fries using infrared dry-blanching as pretreatment. Food Chem. 2012;132:686–692. doi: 10.1016/j.foodchem.2011.10.055. [DOI] [Google Scholar]

- Bingol G, Wang B, Zhang A, Pan Z, McHugh TH. Comparison of water and infrared blanching methods for processing performance and final product quality of French fries. J Food Eng. 2014;121:135–142. doi: 10.1016/j.jfoodeng.2013.08.001. [DOI] [Google Scholar]

- Bognàr A. Comparative study of frying to other cooking techniques influence on the nutritive value. Grasas Aceites. 1998;49(3–4):250–260. doi: 10.3989/gya.1998.v49.i3-4.746. [DOI] [Google Scholar]

- Csallany AS, Han I, Shoeman DW, Chen C, Yuan J. 4-hydroxynonenal (HNE), a toxic aldehyde in French fries from fast food restaurants. J Am Oil Chem Soc. 2015;92:1413–1419. doi: 10.1007/s11746-015-2699-z. [DOI] [Google Scholar]

- Elmore JS, Briddon A, Dodson AT, Muttucumaru N, Halford NG, Mottram DS. Acrylamide in potato crisps processed from 20 UK-grown varieties: Effects of variety and tuber storage time. Food Chem. 2015;182:1–8. doi: 10.1016/j.foodchem.2015.02.103. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Haase NU, Weber L. Ascorbic acid losses during processing of French fries and potato chips. J Food Eng. 2003;56:207–209. doi: 10.1016/S0260-8774(02)00252-2. [DOI] [Google Scholar]

- Jimenez ME, Rossi AM, Sammán NC. Changes during cooking processes in 6 varieties of Andean potatoes (Solanum tuberosum ssp. Andinum) Am J Plant Sci. 2015;6:725–736. doi: 10.4236/ajps.2015.65078. [DOI] [Google Scholar]

- Kita A, Lisińska G. The influence of oil type and frying temperatures on the texture and oil content of French fries. J Sci Food Agric. 2005;85:2600–2604. doi: 10.1002/jsfa.2319. [DOI] [Google Scholar]

- Krokida MK, Oreopoulou V, Maroulis ZB, Marinos-Kouris D. Effect of pre-drying on quality of French fries. J Food Eng. 2001;49:347–354. doi: 10.1016/S0260-8774(00)00233-8. [DOI] [Google Scholar]

- Liu EZ, Scanlon MG. Modelling the effect of blanching conditions on the texture of potato strips. J Food Eng. 2007;81:292–297. doi: 10.1016/j.jfoodeng.2006.08.002. [DOI] [Google Scholar]

- Lloyd BJ, Farkas BE, Keener KM. Quality comparison of French fry style potatoes produced by oven heating, immersion frying and controlled dynamic radiant heating. J Food Proc Preserv. 2004;28(6):460–472. doi: 10.1111/j.1745-4549.2004.23075.x. [DOI] [Google Scholar]

- Mariotti M, Cortés P, Fromberg A, Bysted A, Pedreschi F, Granby K. Heat toxicant contaminant mitigation in potato chips. LWT Food Sci Technol. 2015;60(2):860–866. doi: 10.1016/j.lwt.2014.09.023. [DOI] [Google Scholar]

- Mestdagh F, de Wilde T, Fraselle S, Govaert Y, Ooghe W, Degroodt JM, Verhe R, van Peteghem C, de Meulenaer B. Optimization of the blanching process to reduce acrylamide in fried potatoes. LWT Food Sci Technol. 2008;41(9):1648–1654. doi: 10.1016/j.lwt.2007.10.007. [DOI] [Google Scholar]

- Millin TM, Medina-Meza IG, Walters BC, Huber KC, Rasco BA, Ganjyal GM. Frying oil temperature: impact on physical and structural properties of French fries during the par and finish frying processes. Food Bioprocess Tech. 2016 [Google Scholar]

- Moyano PC, Pedreschi F. Kinetics of oil uptake during frying of potato slices: effect of pre-treatments. LWT Food Sci Technol. 2006;39(3):285–291. doi: 10.1016/j.lwt.2005.01.010. [DOI] [Google Scholar]

- O’Connor CJ, Fish KJ, Smith BG, Melton LD. Fat uptake in French fries as affected by different potato varieties and processing. J Food Sci. 2001;66(6):903–908. doi: 10.1111/j.1365-2621.2001.tb15194.x. [DOI] [Google Scholar]

- Pedreschi F. Frying of potatoes: physical, chemical, and microstructural changes. Dry Technol. 2012;30:707–725. doi: 10.1080/07373937.2012.663845. [DOI] [Google Scholar]

- Pedreschi F, Moyano PC. Effect of pre-drying on texture and oil uptake of potato chips. Lebensmittelwissenschaft und Technologie. 2005;38:599–604. [Google Scholar]

- Pedreschi F, Moyano P, Kaack K, Granby K. Color changes and acrylamide formation in fried potato slices. Food Res Int. 2005;38:1–9. doi: 10.1016/j.foodres.2004.07.002. [DOI] [Google Scholar]

- Pedreschi F, Kaack K, Granby K. The effect of asparaginase on acryilamide formation in French fries. Food Chem. 2008;109:386–392. doi: 10.1016/j.foodchem.2007.12.057. [DOI] [PubMed] [Google Scholar]

- Saguy I, Dana D. Integrated approach to deep fat frying: engineering, nutrition, health and consumer aspects. J Food Eng. 2003;56:143–152. doi: 10.1016/S0260-8774(02)00243-1. [DOI] [Google Scholar]

- Sanz T, Primo-Martin C, van Vliet T. Characterization of crispiness of French fries by fracture and acoustic measurements, effect of pre-frying and final frying times. Food Res Int. 2007;40:63–70. doi: 10.1016/j.foodres.2006.07.013. [DOI] [Google Scholar]

- Teruel MDR, Gordon M, Linares MB, Garrido MD, Ahromrit A, Niranjan K. A comparative study of the characteristics of French fries produced by deep fat frying and air frying. J Food Sci. 2015;80(2):349–358. doi: 10.1111/1750-3841.12753. [DOI] [PubMed] [Google Scholar]

- USDA . Color standards for frozen French fried potatoes. 5. Baltimore: Munsell Color; 2007. [Google Scholar]

- van Koerten KN, Schutyser MAI, Somsen D, Boom RM. Crust morphology and crispness development during deep-fat frying of potato. Food Res Int. 2015;78:336–342. doi: 10.1016/j.foodres.2015.09.022. [DOI] [PubMed] [Google Scholar]

- van Loon WAM, Visser JE, Linssen JPH, Somsen DJ, Klok HJ, Voragen AGJ. Effect of pre-drying and par-frying conditions on the crispness of French fries. Eur Food Res Technol. 2007;225(5–6):929–935. doi: 10.1007/s00217-006-0463-1. [DOI] [Google Scholar]

- Yang Y, Achaerandio I, Pujolà M. Influence of the frying process and potato cultivar on acrylamide formation in French fries. Food Control. 2016;62:216–223. doi: 10.1016/j.foodcont.2015.10.028. [DOI] [Google Scholar]

- Yu B, Jin Z, Deng L, Xu X, He L, Wang J, Tian Y, Chen H. Kinetic study of thermal inactivation of potato peroxidase during high-temperature short-time processing. J Food Sci Technol. 2010;47:67–72. doi: 10.1007/s13197-010-0017-1. [DOI] [PMC free article] [PubMed] [Google Scholar]