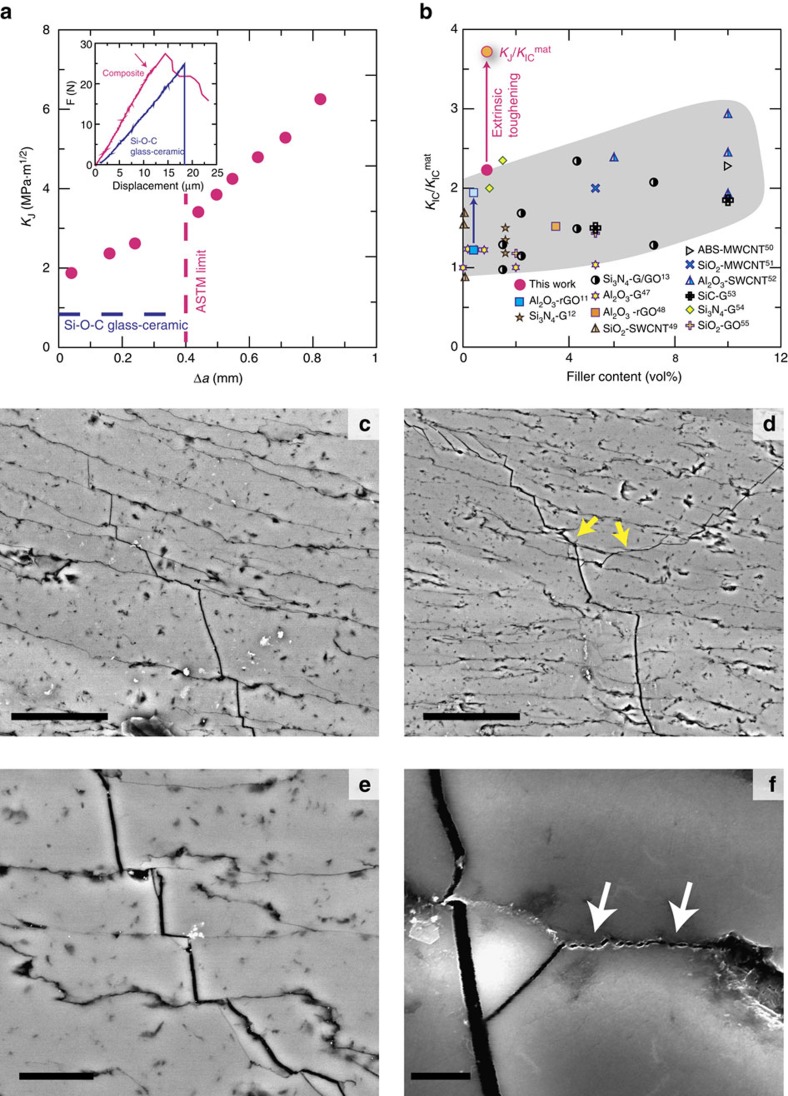

Figure 5. Mechanical response.

(a) While the glass-ceramic is brittle, the composite exhibits stable crack-propagation (insert shows a typical force-displacement curve with the arrow indicating crack initiation, differences in the load-displacement curve slope are probably due to differences in sample and notch sizes rather than to a differences in stiffness) with rising resistance curve (R-curve). The maximum toughness (in terms of KJ) is of the order of 3–3.5 MPa m1/2 (within the ASTM limit) (b) When comparing the fracture resistance to those of other ceramics reinforced with carbon nanostructures it is possible to see that the interconnected network offers very efficient toughening at extremely low carbon contents (KIC is the toughness of the composite and KICmat that of the matrix material). When taking into account extrinsic toughening (as measured in the R-curve) the increase (comparing the final resistance, KJ, for the longer cracks with the toughness of the Si–O–C matrix) is several times higher. (c–f) Several toughening mechanisms could be identified in the scanning electron micrographs taken of the propagating crack. These include crack deflection (c–e), branching (d) and interfacial friction (f). These parallel those observed during the fracture of a natural layered material: nacre. All SEM images in this figure where taken using backscattered electrons. Scale bar, 25 μm (c); 50 μm (d); 10 μm (e); 2 μm (f) (refs 11, 12, 13, 47, 48, 49, 50, 51, 52, 53, 54, 55).