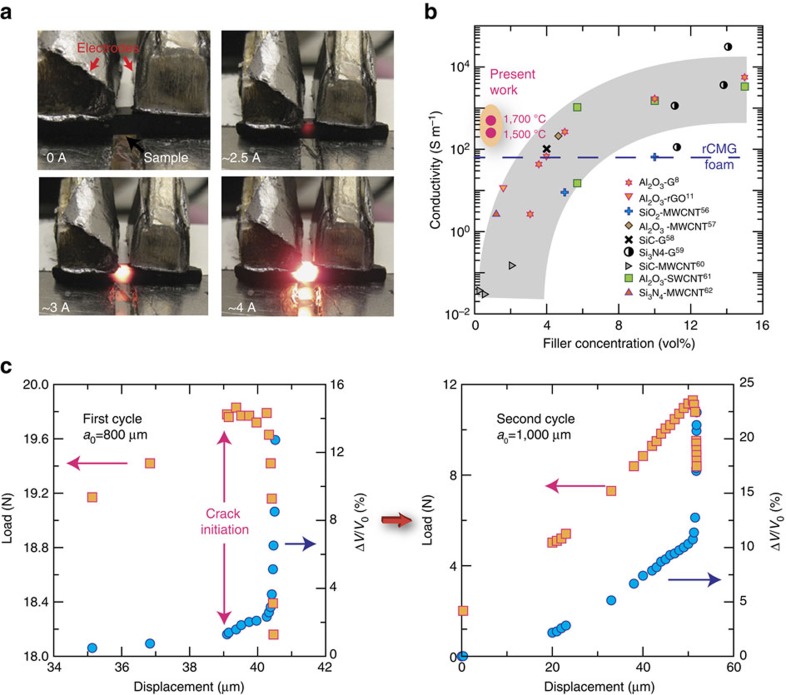

Figure 6. Electrical properties.

(a) Demonstration of the Joule heating effect of the composite (distance between electrodes ∼0.7 mm). (b) Due to its finely interconnected network the electrical conductivities are one to two orders of magnitude higher than for ceramic materials with similar contents of carbon nanofillers (data for composites sintered at two temperatures). (c) Load displacement curves taken during the 4-point bending of a notched sample and simultaneous variation of the voltage taken in using a 4-probe set-up (constant current). The partial disruption of the graphene network by crack formation and propagation can be used to monitor the materials structural integrity. In the first cycle, there is a measurable increase in voltage when a cracks starts to form and propagate. The test was stopped after the crack underwent a length increment of ∼200 μm. Changes in voltage can be detected during initiation when the crack is few microns long (voltage baseline is taken for an initial notch length, ao=800 μm). When the load is released, the crack closes and connection in the network is recovered. After the load is re-applied (second cycle) a gradual increase in voltage is seen almost immediately corresponding to crack opening followed by a step increase when the it starts to propagate8,11,56,57,58,59,60,61,62.