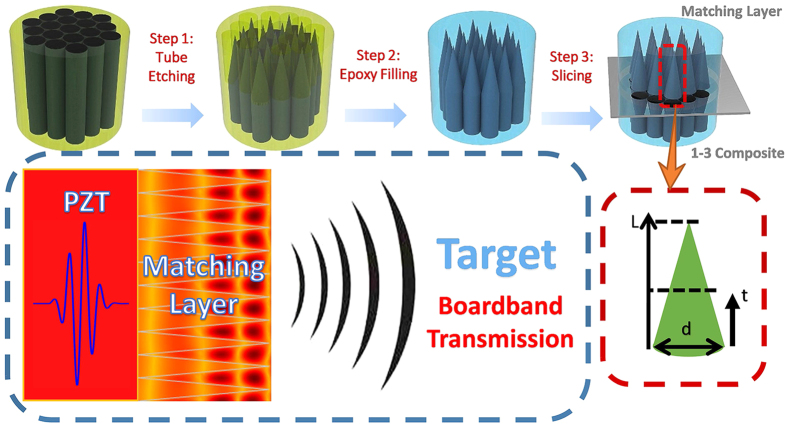

Figure 1. Fabrication of the metamaterial matching layer.

The core arrays were first formed using the tube etching method. After filling the voids with epoxy resin (EPO-TEK 301), the metamaterial matching layer was then extracted via precise cutting and integrated with a piezoelectric material unit to test the broadband acoustic transmission performance. The structure was modelled as a pyramidal cone with a diameter d of 125 μm and taper length L = 610 μm.