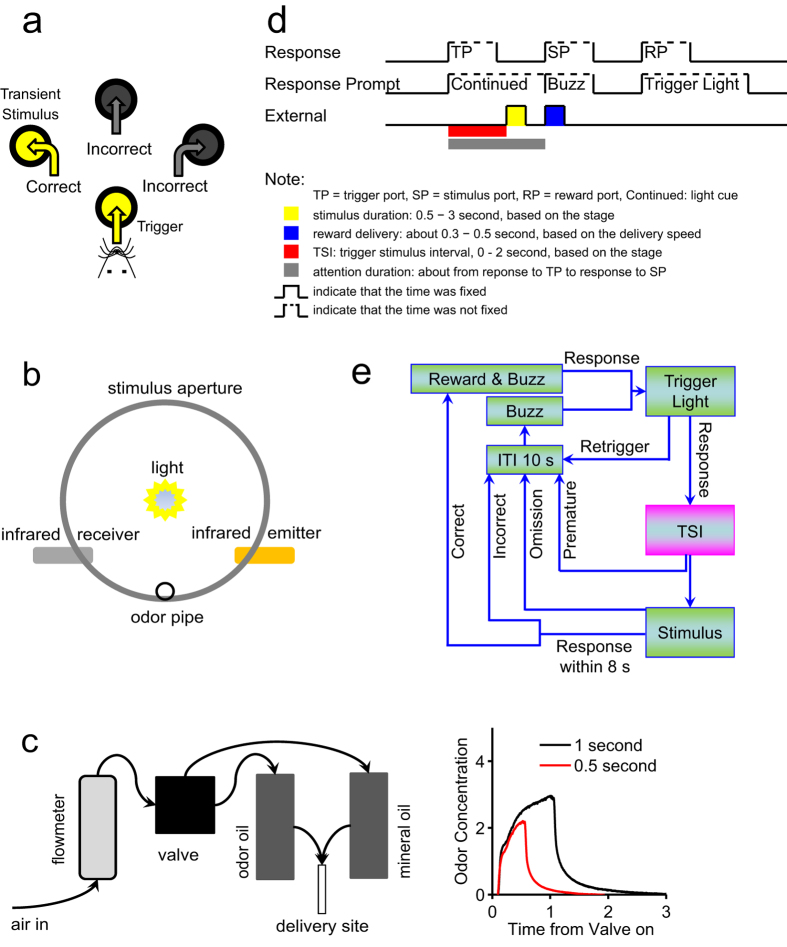

Figure 1. Stimulus delivery apparatus and behavioral test design.

(a) Schematic diagram of the task panel. The water tray was located on the opposite site of the four apertures. (b) Schematic of stimulus aperture. Aperture depth was 2.5 cm, and the light was located at the center of the aperture base. The infrared emitter and receiver were located 0.6 cm from the entrance. For olfactory tasks, the odorant (isoamyl acetate, IAA for short) was delivered at the bottom of the entrance. (c) Setup for odorant delivery. Left: schematic showing components used for odorant delivery. Right: Odorant concentration at the odor outlet. When the valve was open, air passed through mineral oil containing dissolved IAA, allowing its delivery. When the valve was closed, air passed through mineral oil alone. The air flow rate was about 0.8 liter per minute. (d) Schematic representation of trial events. (e) Illustration of the procedure. As training stages advanced, TSIs (0–2 seconds) became longer and the stimulus delivery period (3–0.5 seconds) became shorter. For the test task, TSIs of 1, 1.5 or 2 seconds were used at random. Four responses were possible: correct, animal poked stimulus aperture; incorrect, animal poked non-stimulus aperture; omission, animal did not poke any aperture; and premature, animal poked stimulus aperture before stimulus delivery. “Retrigger” indicated that the trial would be stopped if animal poked the trigger twice within the TSI. Reward-associated buzz was used to speed initiation of a new trial when the rat did not respond correctly.