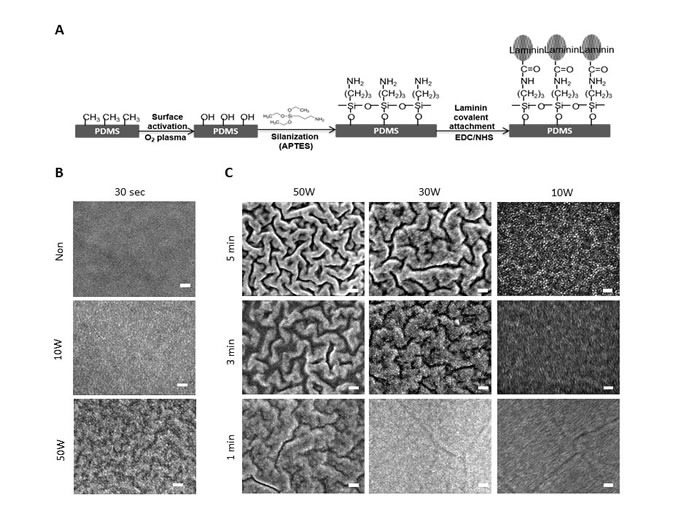

Figure 2. Plasma modified PDMS sheet.

A. Schematic illustration of the surface modification procedure of PDMS. PDMS membranes were generated using medical grade elastomer (Nusil Technology LLC, Inc.), and PDMS surfaces was treated with O2 plasma. After plasma modification, silane solution (APTES) was used to introduce the amine groups (NH2) onto the surface for further protein attachment. Laminin was chemically attached on to the aminated surface via EDC/NHS mediated covalent bonding. In the reaction, the carboxylic acid group son laminin enable to couple with the amine group on PDMS surface and finally form a stable amide bond on PDMS substrate. B. SEM images of PDMS substrate with (10W and 50W) or without plasma treatment for 30 sec. The samples were dried in vacuum and then sputter coated with gold (JFC 1200, JOEL Tokyo, Japan). Images were obtained using a JSM-7600F (JOEL, Tokyo, Japan) SE) with electron beam energy of 5kV. Small granular-like structure appears on PDMS surface after plasma treated at 10W. Wave structure formed on the surface after plasma treated at 50W. Scale bar = 100 nm. C. SEM images of plasma treated ODMS substrates with different plasma exposure time and power. Scale bar = 100 nm.