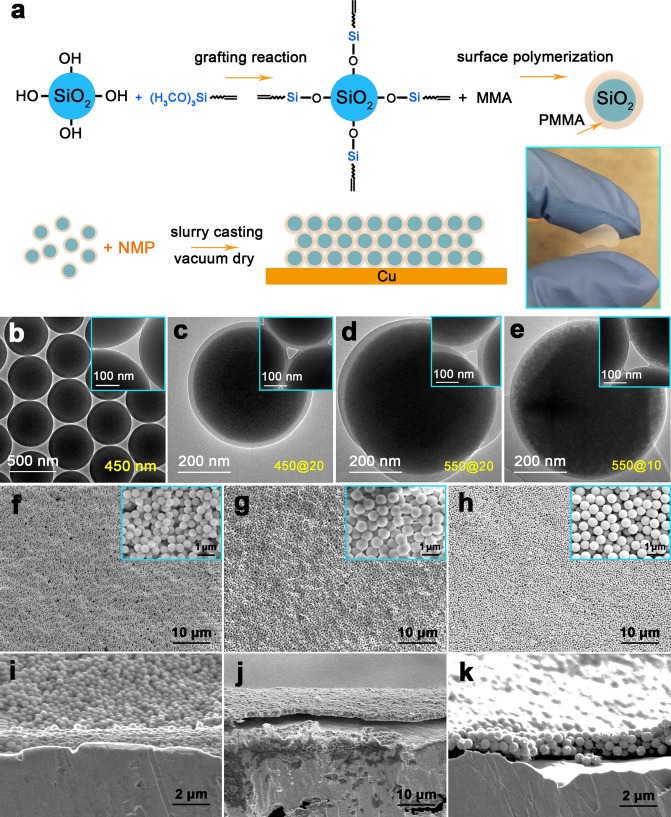

Figure 2.

Schematic diagrams for the preparation of SiO2@PMMA core–shell nanosphere coated electrode and microstructures for nanospheres with various dimensions. (a) SiO2 nanospheres were first functionalized with (H3CO)3Si. Monodisperse SiO2@PMMA core–shell nanospheres were synthesized by seeded emulsion polymerization. SiO2@PMMA nanosphere coated Cu electrodes were synthesized by slurry casting. The inset figure indicates that the membrane (thickness is 5 μm) formed by the SiO2@PMMA core–shell nanospheres is flexible. (b) TEM image of the SiO2 nanospheres. (c–e) TEM images of the SiO2@PMMA nanospheres of (c) 450@20, (d) 550@20, and (e) 550@10 nm. The inset figures show the subtriangular pores formed between three nanospheres with various diameters. (f–k) Top-view and cross-sectional SEM images of the SiO2@PMMA nanospheres with (f, i) 450@20, (g, j) 550@20, and (h, k) 550@10 nm coated on Cu foil.