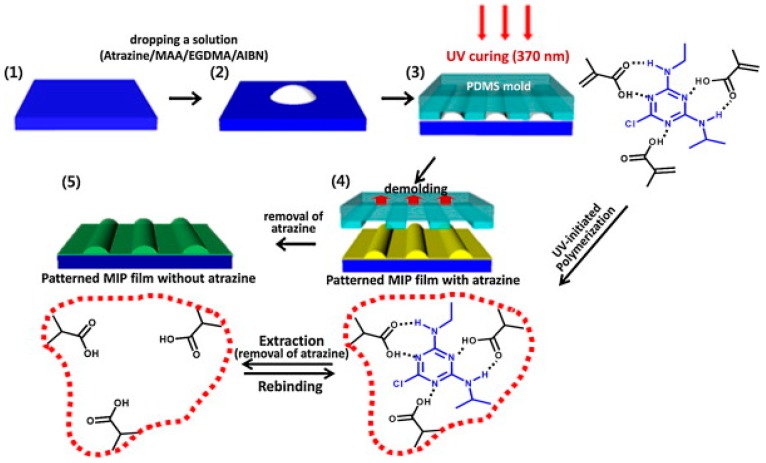

Figure 1.

Schematic representation of fabrication process of patterned MIP films via soft lithography and UV polymerization. (1–2) Imprinting solution containing the template molecule, functional and cross-linking monomers and initiator was dropped on the substrate. (3) The patterned PDMS mold was placed on the droplet of solution under certain pressure to ensure enough physical contact between the PDMS and substrate. Then, UV polymerization was initiated and continued for 7–10 min. (4) Following de-molding, the patterned MIP films were dried at 60 °C. (5) In the last step, template molecule (atrazine) was removed from the surface (reproduced from [29] with permission).