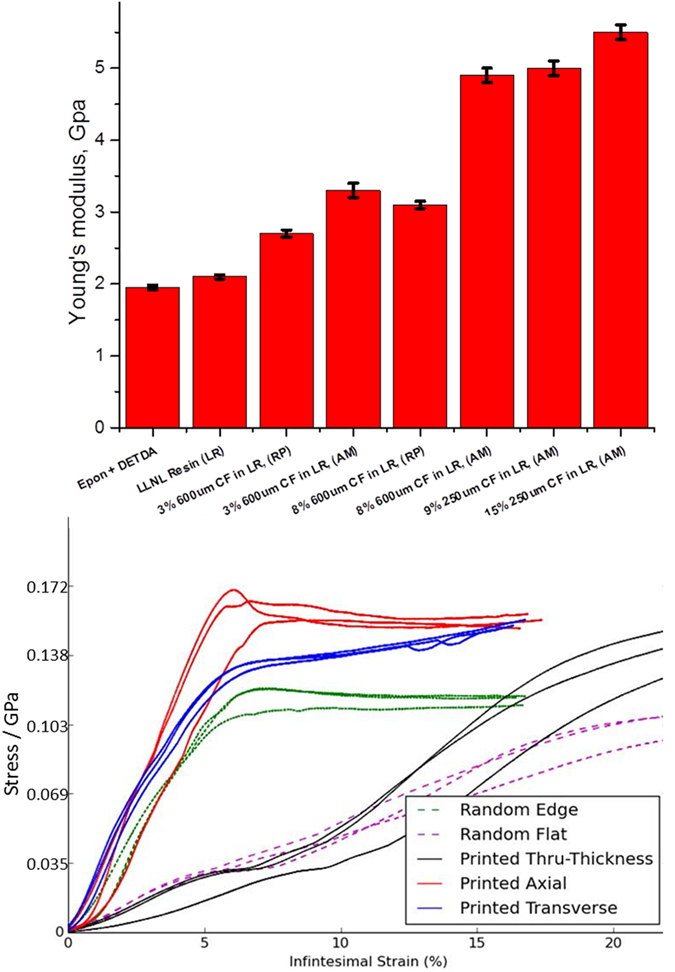

Figure 8. Tensile and compressive testing results from AMCFRC and equivalent vol. fraction random pressed parts.

Upper: Average Young’s modulus as determined by tensile testing for unfilled resins, AMCFRC samples and pressed chopped fiber parts. Two fiber lengths (250 and 600 μm) and 4 volume fractions of fiber (0, 3, 8 & 15%) were investigated RP = random pressed and AM = additively manufactured respectively. In these parts, the preferential direction of fiber alignment will be in line with a single axis, the major axis of printing -referred to as the ‘print direction’ throughout the printed part. This is also illustrated in Fig. 9. Note that the AMCFRC parts outperform random chopped fiber parts even at lower volume fractions of fiber. Lower: compressive testing of 3 vol.% AMCFRC and random parts. Note that AMCFRC parts outperform random chopped parts not only when they are tested axially to the print direction but in both transverse and through thickness modes as well.