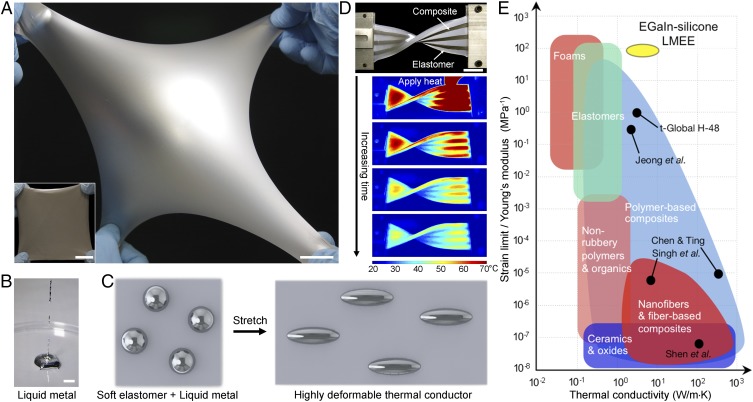

Fig. 1.

Soft, thermally conductive composite. (A) Highly deformable LMEE. (scale bars, 25 mm.) (B) EGaIn alloy is liquid at room temperature and shows fluid characteristics as demonstrated by falling droplets. (Scale bar, 10 mm.) (C) Schematic illustration of the LMEE composite where LM microdoplets are dispersed in an elastomer matrix and, upon deformation, the LM inclusions and elastomer elongate in the direction of stretching. (D) Alternating strips of LMEE and unfilled elastomer are heated with a heat gun, and the IR photo time sequence shows the LMEE dissipating heat more rapidly than the elastomer (images correspond to t = 0, 5, 10, and 15 s after the heat source is removed). (Scale bar, 25 mm.) (E) The ϕ = 50% LMEE composites described here occupy a unique region of the material properties space when comparing thermal conductivity with the ratio of strain limit to Young’s modulus. (Data points are from refs. 2, 9, 12, and 14.)