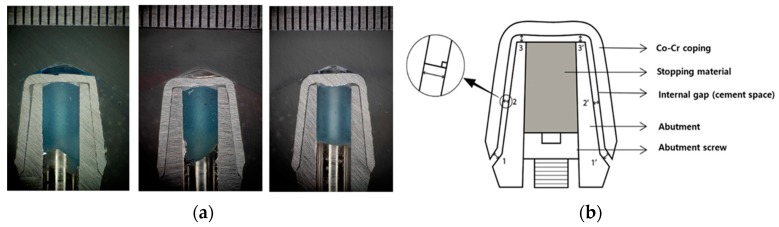

Figure 5.

(a) Specimens for internal gap measurements in the casting, CAD/CAM milled, and laser sintered groups; (b) Schematic view of six standardized measurement areas for internal gap: two marginal point areas (1, 1’), two axial point area (2, 2’), and two occlusal point area (3, 3’). Measurement location of the marginal gaps (1, 1’) was the center of chamfer-area, and the measurement location of axial gaps (2, 2’) was the center of the axial wall, starting at the end-point of the margin and continuing until the transition point with the occlusal area. Measurement location of occlusal gaps (3, 3’) included the center of the occlusal surface of the coping, on both sides of the access hole (5 points × 2 locations × 3 areas × 12 specimens/group). A small circle on the left side shows the internal gap measurements as the perpendicular distance between an outer surface of the abutment and the inner surface of the coping.