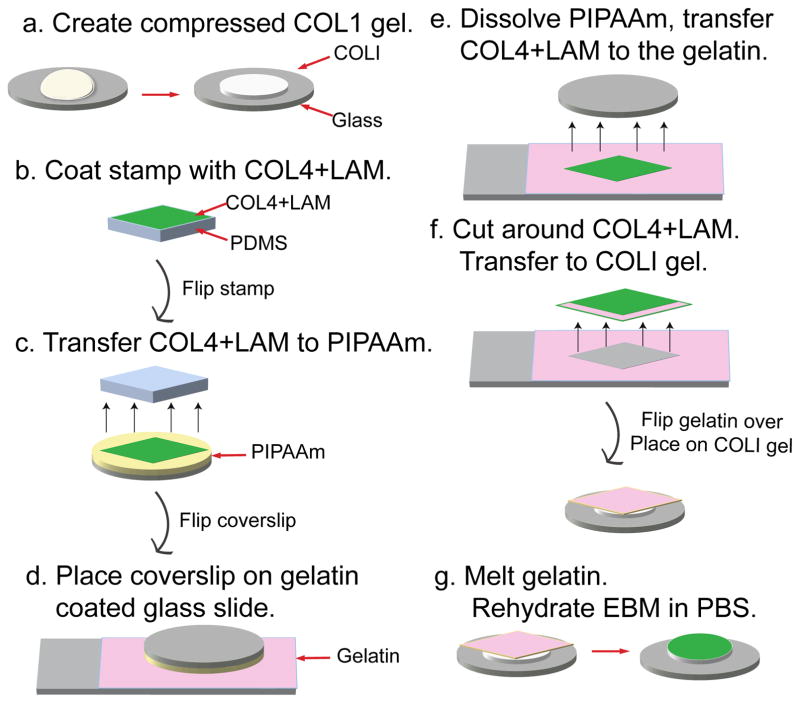

Figure 1. Schematic diagram of the EBM fabrication process.

(a) A 6 mg/mL collagen I gel (COL1) is compressed in a humid incubator at 37 °C for 3 hours. Once compressed, it is dried in a biohood. (b) Flat, featureless PDMS stamps are coated in a mixture of 50 μg/mL collagen IV and 50 μg/mL laminin in PBS (COL4+LAM), for 1 hour. (c) The square sheet of COL4+LAM is brought into conformal contact with a PIPAAm coated coverslip for 1 hour. (d) The coverslip is flipped over so the COL4+LAM sheet is placed down onto a gelatin coated glass slide. (e) The PIPAAm is dissolved by immersing the slide and coverslip in 25 °C distilled water for 5 minutes. (f) The gelatin is cut around the COL4+LAM sheet, peeled away from the glass slide and placed COL4+LAM side down onto the dried compressed COL1 film. (g) The COL4+LAM sheet is transferred to the COL1 by melting the gelatin in an incubator at 37 °C for 45 minutes, followed by rinsing twice with warm PBS, an additional incubation with warm PBS for 45 min and rinsing twice with warm PBS.