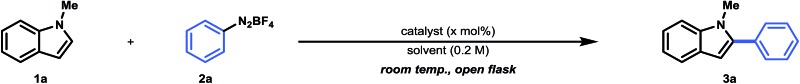

Table 1. Optimization for the Pd-catalyzed C-2 arylation of 1-methylindole a .

| ||||

| Entry | Catalyst (mol%) | Solvent | Reaction time | Yield GC-FID (%) |

| 1 | Pd(OAc)2 (10.0) | DMF | 30 min | 66 |

| 2 | Pd(OAc)2 (5.0) | DMF | 30 min | 34 |

| 3 | — | DMF | 16 h | 0 |

| 4 | Pd(OAc)2 (5.0) | Solvent b | 30 min | <72 |

| 5 | Pd(OAc)2 (5.0) | THF | 30 min | 77; 76 c |

| 6 | Catalyst (5.0) d | THF | 2 h | 0 |

| 7 | Pd(TFA)2 (5.0) | THF | 30 min | 76 |

| 8 | Pd2(dba)3 (2.5) | THF | 30 min | 68 |

| 9 | Pd(OAc)2 (0.5) | THF | 1 h | 81 |

| 10 | Pd(OAc)2 (0.2) | THF | 1 h | Trace |

| 11 | Pd(OAc)2 (0.5) | 2-MeTHF | 2 h | 87 |

| 12 | Pd(OAc)2 (0.5) | EtOAc : 2-MeTHF (1 : 1) | 1 h | 89 |

| 13 | Pd(OAc)2 (0.2) | EtOAc : 2-MeTHF (1 : 1) | 1 h | 78 |

| 14 e | Pd(OAc)2 (0.5) | EtOAc : 2-MeTHF (1 : 1) | 30 min | 93; 90 f |

aReaction conditions: catalyst, 0.5 mmol heteroarene and 1.2 equiv. benzenediazonium tetrafluoroborate in 2.5 mL solvent at rt, 0.1 equiv. decafluorobiphenyl as internal standard for GC-FID, open flask.

bSolvent: H2O, AcOH, EtOAc, propylene carbonate, DMF, acetone, MeCN, Et2O, 1,4-dioxane, MeOH, EtOH, i-PrOH n-BuOH, DCM, DCE, CHCl3, toluene.

cSchlenk line techniques used.

dCatalyst: 10% Pd/C, PdCl2, Cu(OAc)2, Cu(OTf)2, Pd[P(C6H5)3]4, (MeCN)2Pd(ii)Cl2 and (η3–C3H5)2Pd2Cl2, PEPPSI-SIPr.

e2 h premixing of Pd(OAc)2 with 1-methylindole, 1.0 equiv. of benzenediazonium tetrafluoroborate used.

fisolated yield.