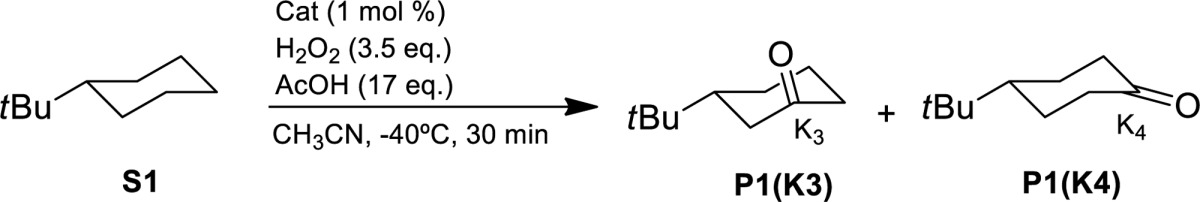

Table 1. Oxidation of tert-Butylcyclohexane (S1) with Different Catalysts.

| entry | cat | conv (%)a | yield (%)a K3 (K4) | K3/K4b | Ee (K3) (%) |

|---|---|---|---|---|---|

| 1c | Fe(mcp) | 62 | 37 (9) | 2.1 | 2 |

| 2c | Fe(pdp) | 48 | 25 (6) | 2.0 | 6 |

| 3 | Mn(mcp) | 46 | 32 (7) | 2.3 | 9 |

| 4 | Mn(pdp) | 86 | 56 (13) | 2.2 | 3 |

| 5c | Fe(TIPSmcp) | 73 | 61 (10) | 3.1 | 33 |

| 6c | Fe(TIPSpdp) | 88 | 53 (17) | 1.6 | 15 |

| 7 | Mn(Me2Npdp) | 37 | 13 (3) | 2.2 | 8 |

| 8 | Mn(dMMpdp) | 93 | 50 (11) | 2.3 | 8 |

| 9 | Mn(BzImpdp) | 79 | 50 (11) | 2.3 | 11 |

| 10 | Mn(CF3mcp) | 55 | 22 (5) | 2.2 | 2 |

| 11 | Mn(TIPSmcp) | 77 | 53 (19) | 1.4 | 44 |

| 12 | Mn(TIPSpdp) | 51 | 22 (7) | 1.6 | 34 |

| 13d | Mn(TIPSecp) | 87 | 51 (15) | 1.7 | 43 |

| 14 | Mn(TIPScpcp) | 68 | 32 (12) | 1.3 | 32 |

| 15 | Mn(TIPSchcp) | 45 | 10 (6) | 1.0 | 6 |

| 16 | Mn(TIPStBucp) | 48 | 8 (5) | 1.0 | Rac |

Conversions and yields determined from crude reaction mixtures by GC. Ee’s determined by GC with chiral stationary phase.

Normalized ratio.

Reaction conditions: Fe catalyst (3 mol %), H2O2 (2.5 equiv), AcOH (1.5 equiv) in CH3CN at 0 °C during 30 min.

(S,S)-Mn-(TIPSecp) (2 mol %).