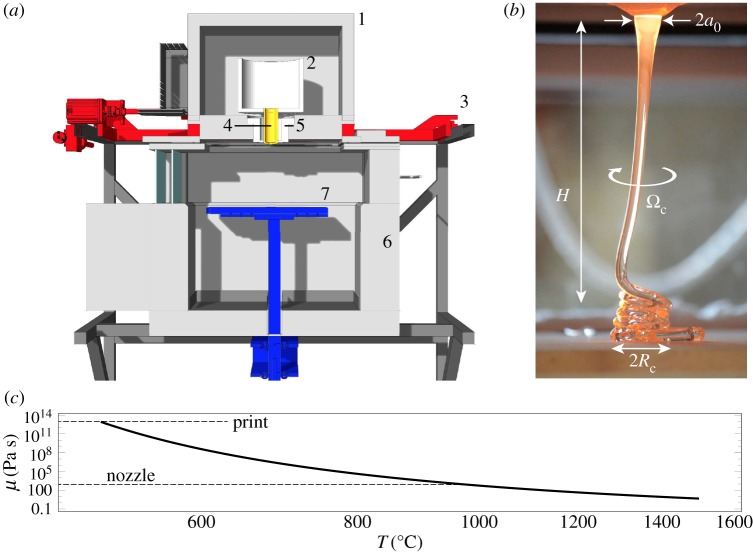

Figure 1.

Experimental set-up. (a) Schematic view of the 3D printer, which comprises (1) the crucible kiln, (2) crucible, (3) xy-motion stage, (4) the nozzle, (5) nozzle kiln, (6) annealing kiln, (7) ceramic build plate and z-axis motion. (b) Thread of initial radius a0 falling from a distance H onto the print plate. The thread accelerates under the action of gravity so that its radius decreases during the fall and buckles under its own weight. The coiling motion is characterized by the radius Rc and frequency Ωc. (c) Dynamic viscosity, μ, of the glass thread plotted as a function of temperature as prescribed in equation (2.1), using data from [23]. (Online version in colour.)