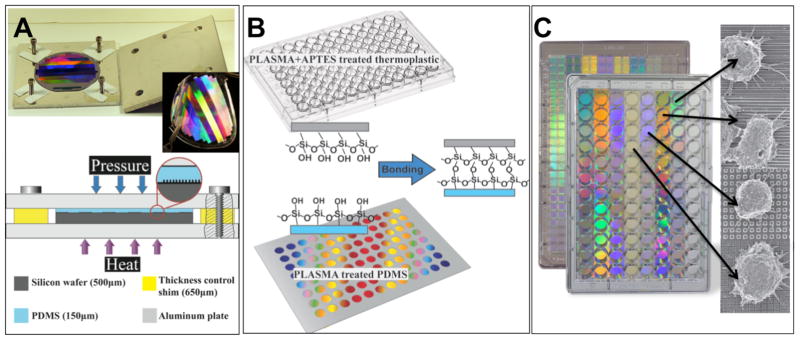

Figure 1.

IMP fabrication process. A. Bonded plates assembly, PDMS thickness is controlled by changing the relative thickness of Si wafer and the shims in four corners, PDMS sheet thickness is ~150 μm; B. Thermoplastic plate is first O2 plasma treated for 1 min and then treated with 1.5% of APTES solution for 20 min, patterned PDMS substrate is O2 plasma treated for 1 min, a silane coupling reaction followed by amine–epoxy bond formation at the interfaces of treated thermoplastic and PDMS at room temperature; C. Integrated mechanobiology platform, in a 96 well plate configuration. The bottom surface of the plate is composed of PDMS nanotopographies.