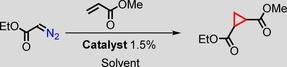

Table 1.

Screening of reaction conditions for the cyclopropanation of methylacrylate with EDA.[a]

| Entry | Catalyst | Solvent | T [°C] | t [h] | Yield [%][b] | trans/cis [c] |

|---|---|---|---|---|---|---|

| 1 | – | CH2Cl2 | 20 | 1 | 0 | – |

| 2 | Co(OAc)2⋅4 H2O | CH2Cl2 | 20 | 1 | <5 | – |

| 3 | [Co(TPP)] | CH2Cl2 | 20 | 20 | 67 | 88:12 |

| 4 | [Co(TPP)] | CH2Cl2 | 10 | 20 | 58 | 88:12 |

| 5 | [Co(salen)] | CH2Cl2 | 20 | 18 | 43 | 70:30 |

| 6 | [Co(BzMeTAA)] | PhMe | 20 | 1 | 97 | 94:6 |

| 7 | [Co(MePhTAA)] | CH2Cl2 | 20 | 1 | 90 | 89:10 |

| 8[d] | [Co(MeTAA)] | CH2Cl2 | 20 | 1 | 87 | 93:7 |

| 9 | [Co(MeTAA)] | CH2Cl2 | 20 | 1 | 85 | 93:7 |

| 10 | [Co(MeTAA)] | THF | 20 | 1 | 72 | 94:6 |

| 11 | [Co(MeTAA)] | PhMe | 20 | 1 | 74 | 95:5 |

| 12 | [Co(MeTAA)] | PhCl | 20 | 1 | 69 | 93:7 |

| 13 | [Co(MeTAA)] | CH3CN: CH2Cl2 (4:1) | 20 | 1 | 80 | 93:7 |

| 14 | [Co(MeTAA)] | CH3OH: CH2Cl2 (4:1) | 20 | 1 | 84 | 94:6 |

| 15 | [Co(MeTAA)] | CH2Cl2 | 10 | 1 | 80 | 93:7 |

| 16 | [Co(MeTAA)] | CH2Cl2 | 0 | 2 | 74 | 97:3 |

| 17 | [Co(MeTAA)] | CH2Cl2 | −78 | 5 | 67 | 99:1 |

| 18[e] | [Co(MeTAA)] | PhMe | 10 | 1 1 2 6 | 85[f] 83[g] 75[h] 14[i] | 96:4 96:4 95:5 95:5 |

[a] Reactions were performed under N2 with 1.0 equiv. of EDA, 3.0 equiv. of methylacrylate and 1.5 mol % catalyst. Concentration: 1.9 mmol EDA/5 mL solvent. [b] Isolated yields. [c] Determined by using GC. [d] 1.0 equiv. methylacrylate, 1.2 equiv. EDA and 1.5 mol % catalyst. [e] Recyclability study performed starting with 5.0 mol % catalyst; [f] cycle 1; [g] cycle 2; [h] cycle 3; [i] cycle 4.