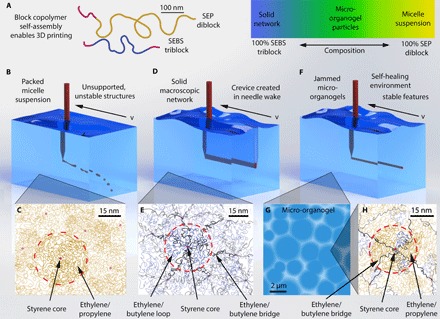

Fig. 1. Block copolymer self-assemblies and micro-organogels.

(A) Organogel support materials are formulated with light mineral oil, polystyrene-block-polyethylene/propylene diblock copolymers, and polystyrene-block-polyethylene/butylene-block-polystyrene triblock copolymers (polymers drawn are extended to illustrate their contour lengths). (B) High concentrations of diblock copolymers result in a fluid phase of packed micelles, unable to support printed structures. (C) Diblock micelles consist of polystyrene cores (red dots) surrounded by ethylene/propylene coronas. (D) At high concentrations of triblock copolymers, the support bath becomes globally cross-linked, and the printing nozzle causes permanent damage as it moves across the gel. (E) Ethylene/butylene midblocks assemble either into cross-link “bridges,” in which the polystyrene endblocks are found in different cores, or into “loops,” in which both polystyrene endblocks are located in the same core. (F and G) An equal blend of diblock and triblock copolymers results in closely packed microgels. Packed microgels provide a self-healing environment, allowing a printing nozzle to repeatedly transverse the same region while simultaneously supporting printed structures. (H) The micro-organogels form when the diblock copolymers replace the triblock copolymers, reducing the number of ethylene/butylene bridges that form until the material is no longer a continuous network.