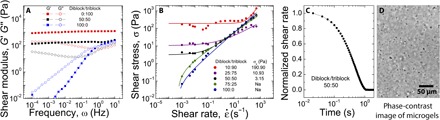

Fig. 2. Rheological characterization of block copolymer phases.

The rheological properties, including frequency sweep (A) and yield stress (B) of block copolymer assemblies, are highly dependent on the ratio of diblock to triblock copolymers. At high diblock concentrations, the material demonstrates rheological properties associated with a liquid, including a crossover in the shear modulus at high frequencies and no determinable yield stress. At high triblock concentrations, the material shows rheological properties associated with an irreversibly cross-linked gel, including separated elastic and viscous shear modulus at high values and irrecoverable yielding at high stresses. Block copolymer blends show rheological properties favorable for 3D printing of soft materials, including separated elastic and viscous shear moduli with low elastic modulus, a low yield stress, and a fast recovery of elasticity after shearing. (C) Thixotropic response time of the block copolymer microgel system. (D) The samples exhibiting rheology suitable for 3D printing are found to be composed of 2- to 4-μm microgels, as seen in phase-contrast microscopy.