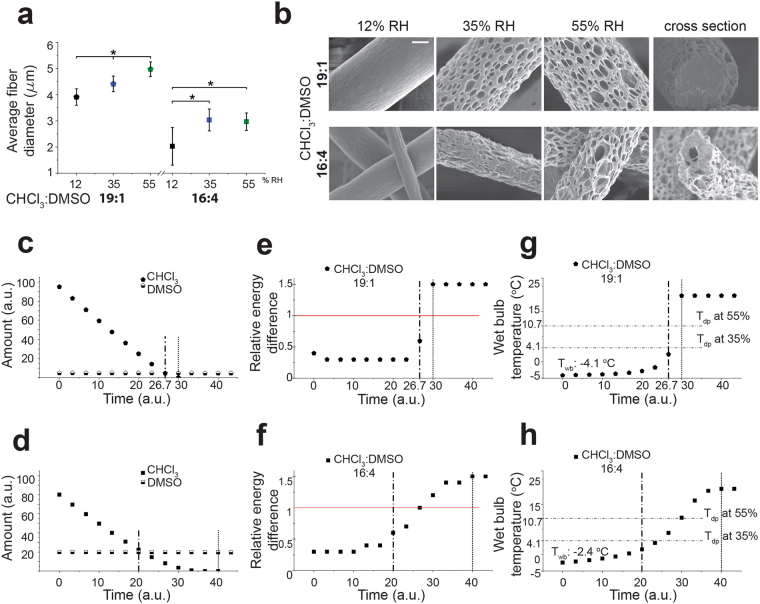

Figure 4.

Resulting PCL fiber morphologies, simulated solvent evaporation and RED value changes during fiber formation for the solvent systems CHCl3:DMSO: (a) Average fiber diameter of electrospun fibers from CHCl3: DMSO with 19:1 and 16:4 ratios, Data represent means ± s.d. *P < 0.05; ANOVA One-way test, (b) SEM micrographs of electrospun fibers from CHCl3: DMSO solutions with 19:1 ratio (upper row) and 16:4 ratio (lower row) at 12, 35 and 55% RH, respectively (scale bar: 1 µm), (c,d) simulated evaporation of CHCl3 and DMSO from PCL solutions with 19:1 and 16:4 ratio, respectively (assuming the initial total amount of the solution is 100 parts and the solvent amount changes by evaporation during electrospinning), (e,f) simulated RED value change during solvent evaporation from CHCl3: DMSO solutions with 19:1 and 16:4 ratios, respectively, (g,h) wet bulb temperature change (°C) during solvent evaporation from CHCl3:DMSO solutions with 19:1 and 16:4 ratio, respectively, (dash-dot line) last time point of similar amounts of solvent (S) and non-solvent; (round dot line) time point S = 0; (red line) solubility limit for the polymer in the solvent system).